On Thursday this week, The Ace Hotel in Sydney was host to A. Lange & Söhne and Watches of Switzerland to present a watch making class to VIP clients and media, building out the Energy Transmission gear train of an automatic watch.

Watchmaking is an art. It’s also a science that involves a lot of mechanical knowledge, maths and physics. When the two come together, this is when you see great watchmaking. And one of the great watchmaking brands is A. Lange & Söhne. It’s hard to deny that their movements are some of the best in the business, and when we were invited to their latest Connoisseurs Akademie workshop in Sydney this week, well lets just say I jumped at the chance!

A. Lange & Söhne has a history dating back almost 200 years, and has become one of the world’s most respected brands with some of the most beautiful movements in the business today. Whilst other brands are using new technologies and materials, A. Lange & Söhne is still very much traditional, using techniques and materials that are the same as they were 100 years ago, like German Silver, blue fired screws and all decorative elements finished by hand engravers with their own individual style. A single watch can take up to six months to produce, and when you see exactly what goes into these pieces, you then understand why.

A. Lange & Söhne are giving selected people around the world the chance to see this, understand it and try their hand at putting together part of a simple movement via their Connoisseurs Akademie. The Ace Hotel in Sydney was the venue, hosted by Watches of Switzerland and A. Lange & Söhne, with some lucky VIP’s and media being taken through a class by A. Lange & Söhne’s very own “Flying Watchmaker” David Weber, who has been with the brand for over 18 years, and a second generation watchmaker with his father, Manfred Weber, also a master watchmaker too.

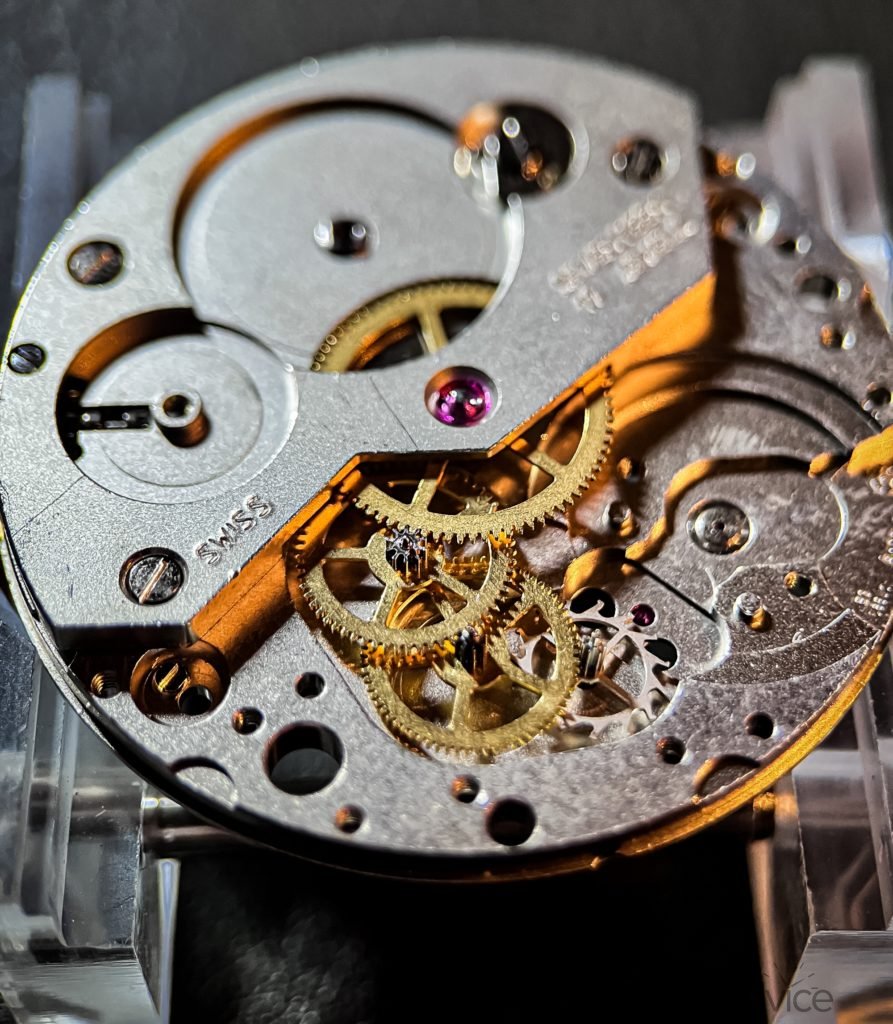

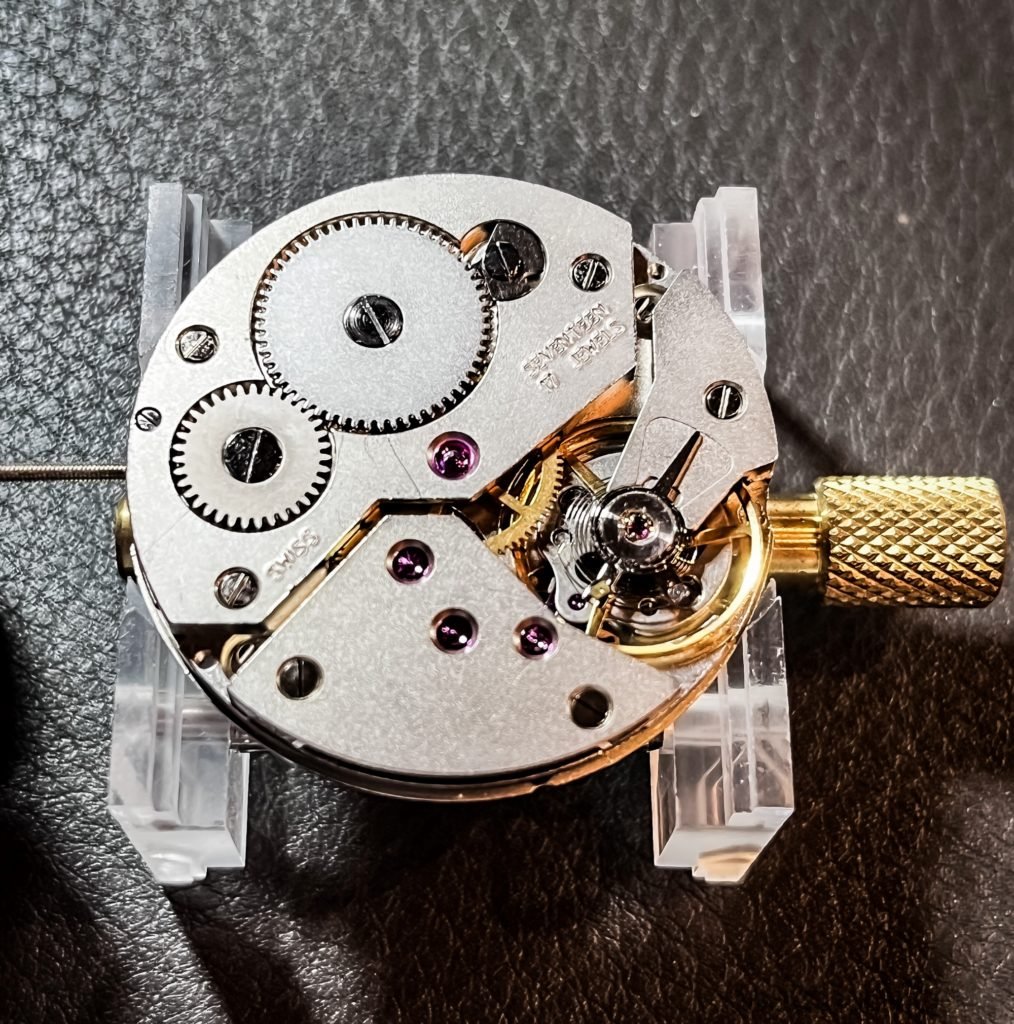

The class was how to assemble the gear train of the watch, which is in essence, the way the energy is transferred from the barrel to the balance spring which regulates the timing. Whilst this was a workshop run by A. Lange & Söhne, we were assembling a basic ETA hound wound movement, after all, the theory is the same and the brand wasn’t going to let us play with actual Lange movements given their apprentices don’t work on them until their last 3 months of their apprenticeship!

But, before we get into the workshop in detail, check out the time-lapse video I took which shows the movement being assembled. Essentially about an hour of actual work condensed into a minute!

Assembling The Gear Train

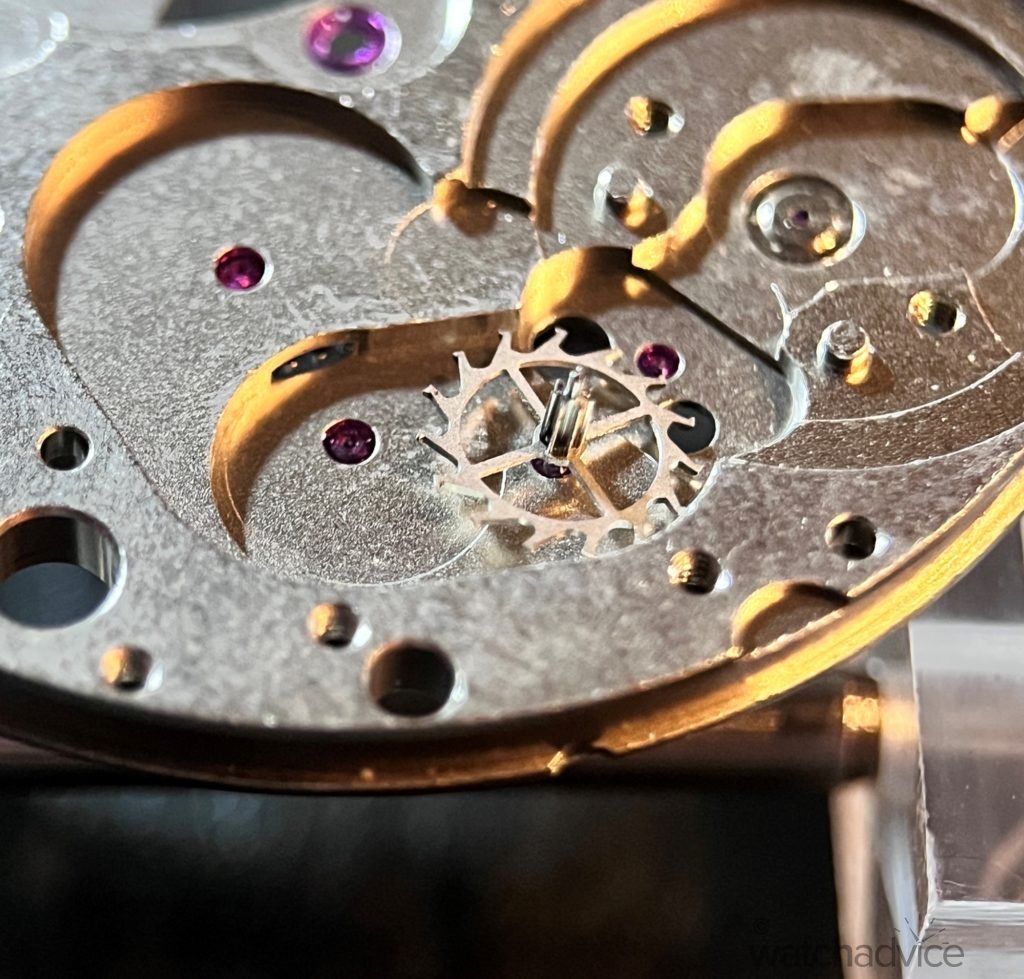

We started by taking the main plate and secured that to the clamp before placing the Escape Wheel into the first jewel. The one thing that instantly strikes me is that the small stem of the Escape Wheel doesn’t slot into anything, but merely rests in the gem itself, which I’ve not thought about in much detail before.

The barrel is the next to be fitted. Slightly easier as it’s just placed over the brushing from the main plate itself. The spring inside the barrel is already wound for us, no need to do this. In the case of the A. Lange & Söhne movements, their springs in their barrels are super fine, and can extend up to 1.86m in a single barrel and with 2 barrels can ensure accuracy over 31 days due to the constant torque between the barrels, which is amazing when you think about it!

After the barrel, we then place in wheels three and four, which both connect to the Escape Wheel in order for the minute wheel to be placed between the second wheel and the barrel. These parts slot into their positions easily, at least as I found it, and at this point, you can really see the movement taking shape and see how the power is being transferred to the balance and regulator.

The Barrel Bridge goes on next, and this secures the Barrel and Minute Wheels in place, in turn secured to the main plate with 2 screws. We’re using plain old ordinary steel screws here, but in the case of the A. Lange & Söhne movements, their screws are all blue fired, and given their movements are smaller and more delicate, so are the screws.

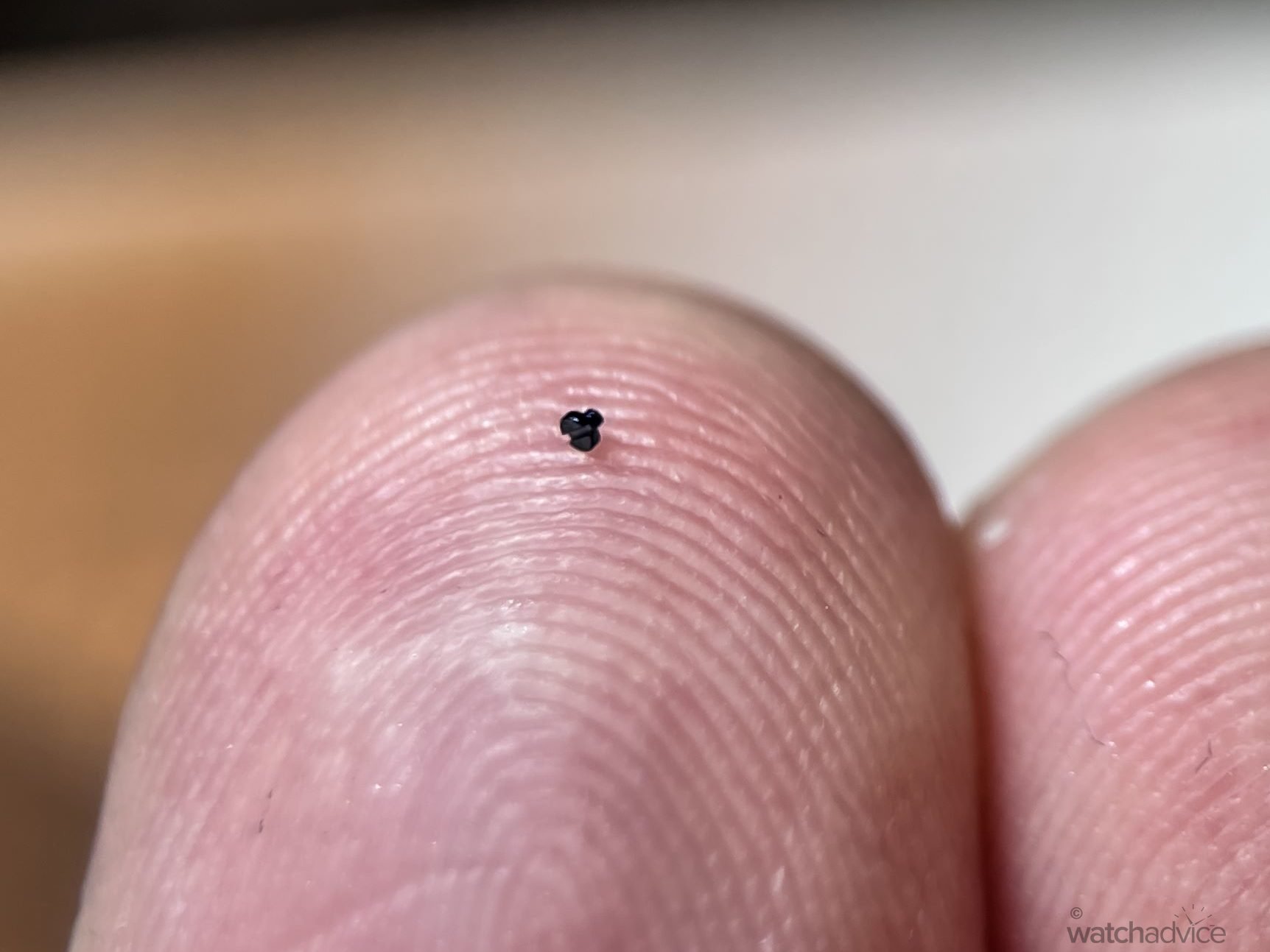

Charles Langlois, who is A. Lange & Söhne South East Asia Managing Director comes over to show me the actual screws in the Lange movements. One is the largest they use, which is smaller than anything we’re using today, and the other is the smallest – shown in the image below resting on the tip of my index finger. No larger than a small speck of sand.

Now that the Barrel Bridge is on, we take the Gear Train Bridge and place this on top of the Third, Forth and Escape Wheels. This is slightly tricky as the wheels are on stems or pinions that aren’t actually fixed into anything, so you need to delicately place the bridge down, and manoeuvre the wheels ever so slightly so they slot into the rubies in the bridge. It takes several goes, and if you’re not careful, you can snap the stems. Thankfully it’s a success.

After this, the Crown Wheel, which is attached to the Crown Stem and Ratchet Wheel are placed on top of the Barrel Bridge. This part of the assembly allows the movement to be wound via the crown as the Crown Wheel connects directly with the stem, and in turn connects with the Ratchet Wheel siting directly above the Barrel. Turn the crown, this winds the Crown Wheel and the Ratchet Wheel, which then winds the Barrel up to power the gear train.

This next step is probably the hardest, and took a lot longer than I anticipated to put together. Whilst not officially part of the workshop, I was determined to place the Pallet Fork in, which links in with the Balance Wheel to regulate the spring. Setting the fork isn’t easy, due to the size of it, and you definitely need the loupe to do this. Once placed on the main plate, you need to secure the Pallet fork with the Pallet Bridge. If not done correctly, the Gear Train will run, but the power will not be regulated due to the fork and balance spring not connecting, i.e. won’t be accurate at all!

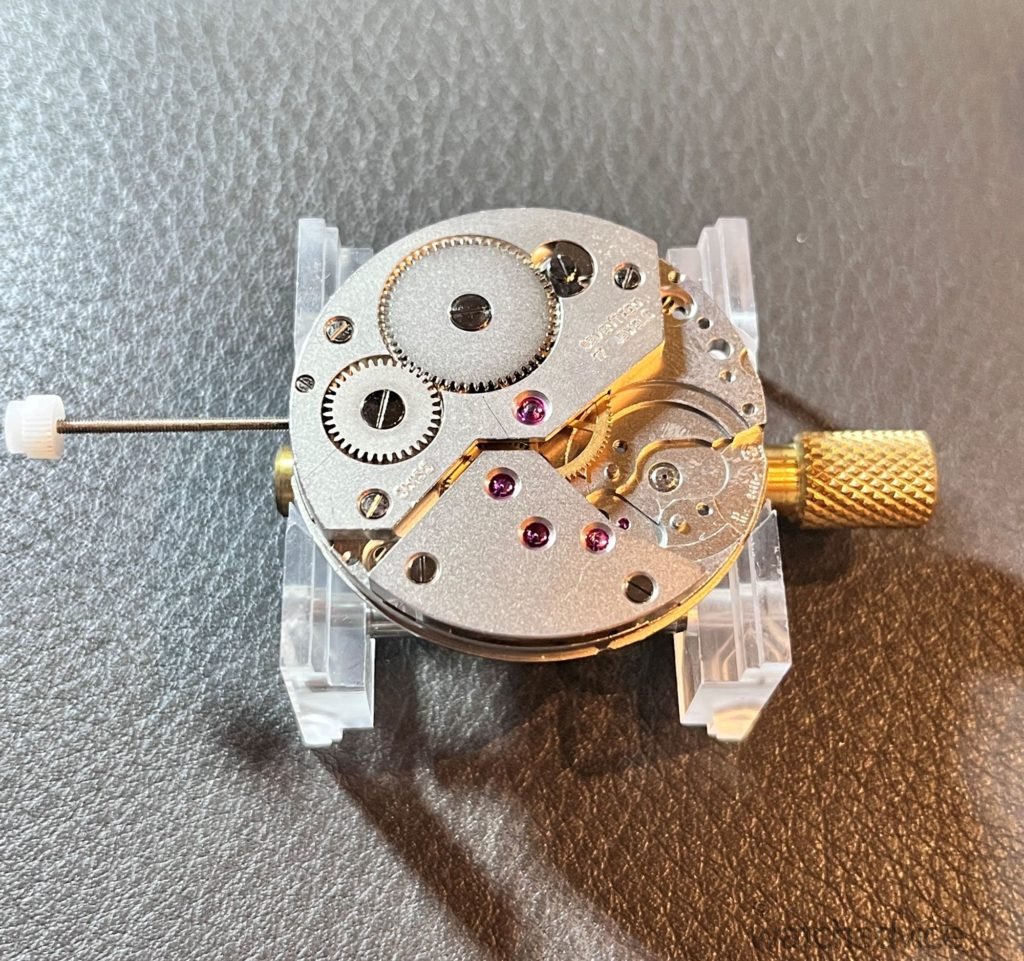

Once this is done, the Balance Spring then goes on last. The Balance is pre-assembled here on the cock already, so with this movement, it just needs to be placed accurately and set in place, and securely screwed down.

You know fairly fast if you’ve done this right as the movement will either work and you can see the Pallet fork flicking back and forth along with the Balance Spring, or you won’t. The first 3 attempts are a fail for me. But finally, I did manage to get it right and working. Whilst this section was technically not part of the workshop, I couldn’t have an unfinished movement on my table!

Final Thoughts

The A. Lange & Söhne Connoisseurs Akademie is a great way to learn more about both the brand, and movement theory 101. The class itself was interesting and you learn what it takes to assemble even a basic movement. And whilst doing so, you gain much more appreciation for the art of watchmaking and even more so when you listen to David Weber talk about how Lange does it.

Whilst I had a very big appreciation for A. Lange & Söhne already, I did walk away with even more respect for the brand. They have stuck with tradition, and are very proud of this, which is quite apparent when you talk to David Weber or Charles Langlois. And whilst other brands use newer materials and technology, A. Lange & Söhne still do it the way they did a century ago, and to me, there is something special in this.

It means there is more effort, skill and craftmanship involved in each watch. The skill involved in crafting the movement pieces, such as the chain in the Fusée-Chain Mechanism, which is completely hand assembled over 2 weeks and made from untreated steel to save friction and weight to ensure maximum accuracy. If a single mistake is made, such as being touched by the hands, then it can corrode over time, and the whole chain needs to be made again.

This is Lange quality and workmanship right here. Once you understand this, your appreciation for what’s on your wrist, should you be lucky enough to own a piece by A. Lange & Söhne, goes up ten fold. Old world craftsmanship still very much has a place in 2023 – I would say more so than ever in a world becoming more automated and commoditised than ever. Hand made is getting rarer and rarer and this to me is what makes a large part of the appeal of a luxury watch.

A big thanks to the Ace Hotel Sydney for having us, Watches Of Switzerland for hosting and A. Lange & Söhne for teaching. Most of the amazing photo’s in this article are taken by Vassi Lena. For more of her work, check out her site – www.vassi.com.au