Glashütte Original is one of my favourite brands, and I’ve always wanted to know as much as I can about everything they do. So what better way to do that than by taking a trip over to Glashütte and checking it out in person?

The watch world is much larger than most people realise. When you think of horology, two destinations usually come to mind: Switzerland and Japan. Both are dominant in their own right and responsible for much of the heritage and innovation that watch brands still draw on today.

Look closer, though, and another destination stands out: Germany. Known for its precision, design and distinct aesthetic, it is an established horological superpower. Brands such as Sinn, D. Dornbluth & Sohn, Stowa and Alexander Shorokoff have all made their mark, but one town has become synonymous with German watchmaking. That town is Glashütte – the epicentre of the country’s horological tradition.

Few brands represent this location like Glashütte Original, which continues to uphold the standards set centuries ago. It’s a story not widely known, so this past summer (or Aussie winter) I travelled to Germany at the brand’s invitation to experience it for myself.

Getting to Glashütte

The morning of the visit, I wasn’t in Glashütte at all – I was about 200 kilometres north in Berlin. After an early departure from my accommodation, I made my way to Berlin Hauptbahnhof, where I boarded a high-speed train bound for Dresden. A reputable watchmaking city in its own right, Dresden would serve as my base for the trip.

After checking into my hotel and dropping off my bags, I was back on the road with a driver sent to collect me. He spoke little English, but my basic German was enough to confirm I was in the right car. The drive to Glashütte was an experience in itself, especially once we hit the Autobahn.

For those unfamiliar, the Autobahn is Germany’s highway system where, on certain stretches, there are effectively no speed limits. While a recommended speed of 130 km/h exists, my driver had no interest in easing off the accelerator. Eventually, the thrill of that ride gave way to the calm of winding forest roads leading into Glashütte. The scenery was breathtaking – the kind that feels like a fairytale.

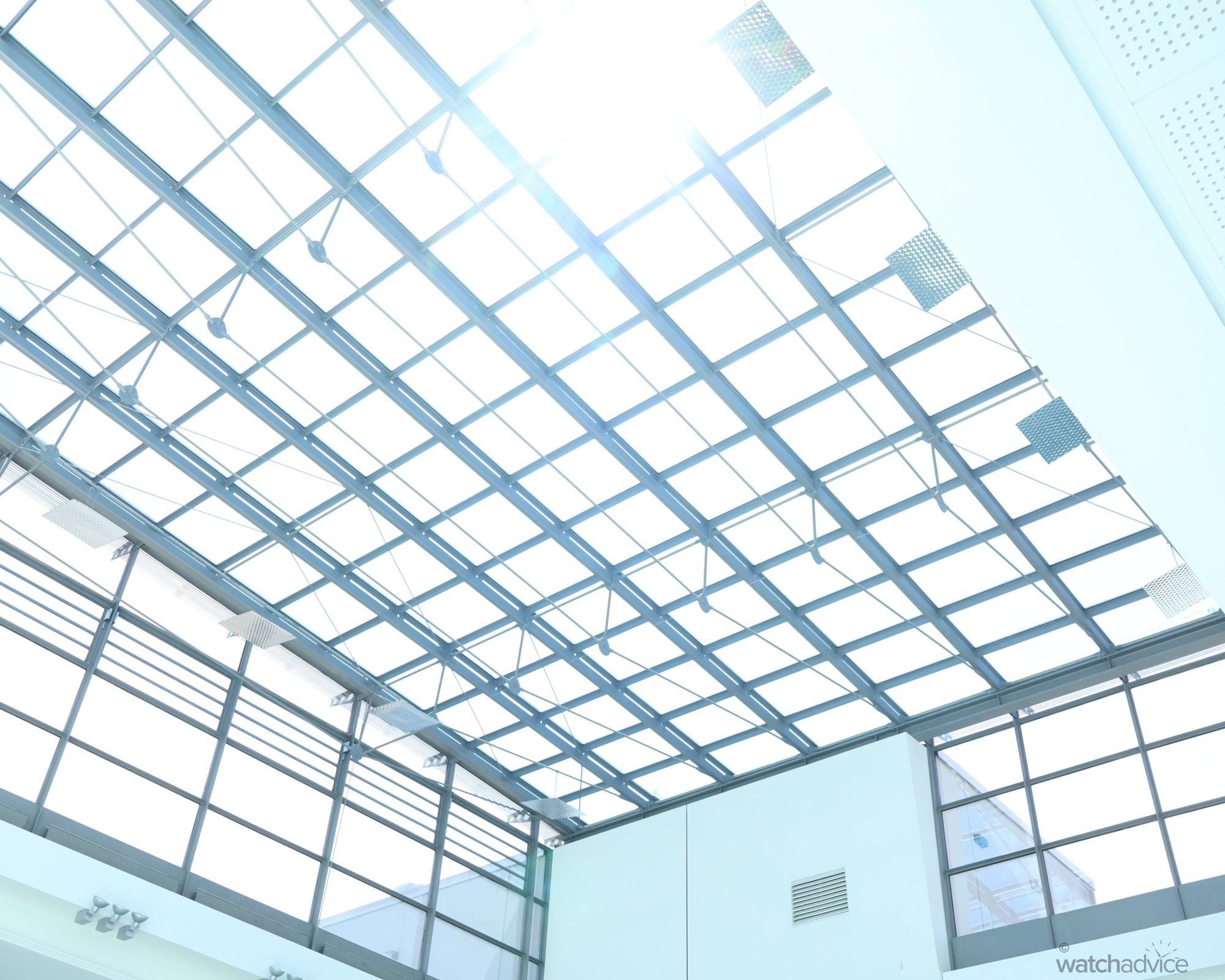

Before long, we arrived at the Glashütte Original manufactory. I thanked the driver and stepped inside, immediately struck by the vast, multi-storey atrium. At its centre stood an exhibition showcasing the brand’s history and current collections. There I met my guides for the day. Ulrike, head of Corporate Communications, would serve as my guide throughout the manufacture, while René escorted me through the town afterwards. Both were warm and welcoming, setting the tone for what proved to be an insightful visit.

Der Uhrenmanufaktur

I’m a watch nerd, not an engineer, but I hoped my enthusiasm would compensate for any gaps in technical knowledge. With that in mind, I set out to absorb as much as I could through the lens Glashütte Original offered – and there was a lot to take in.

My tour with Ulrike followed the brand’s ‘Learning Path,’ a structured walkthrough of the manufacture that combined explanation with direct observation of daily operations. The only area off-limits was the Design and Prototype Department, which understandably remain behind closed doors.

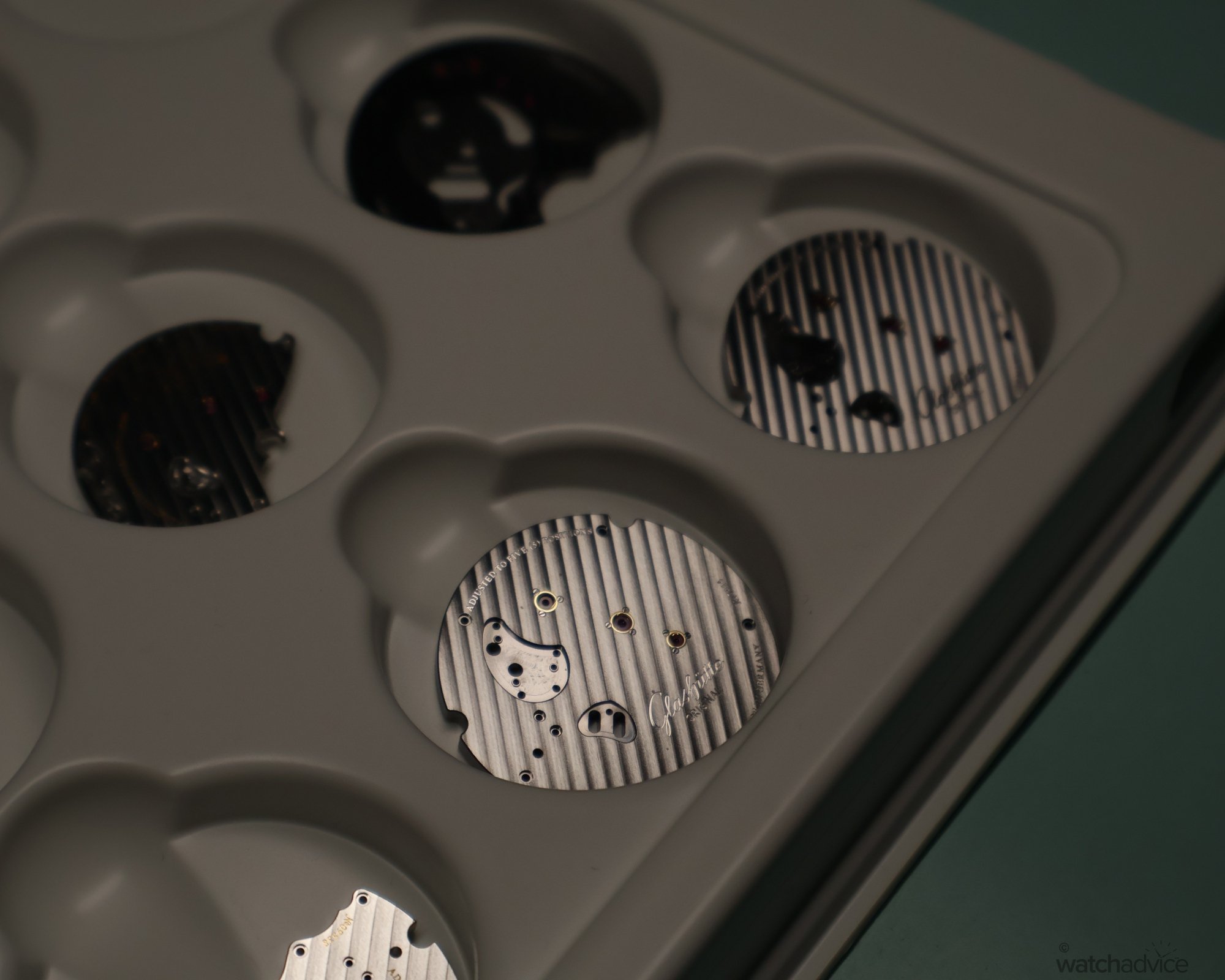

We began on the ground floor, where heavy-duty machinery shapes the components of each movement. Everything from automatic rotors, bridges and base plates to swan-neck springs, levers and tourbillon cages starts life here. Two methods are used: CNC, where computer-controlled machines cut precise shapes, and spark erosion, where delicate parts are formed by electrical sparks in a special fluid. The latter allows for exceptionally fine details, such as sharp corners and intricate patterns, even in the hardest materials.

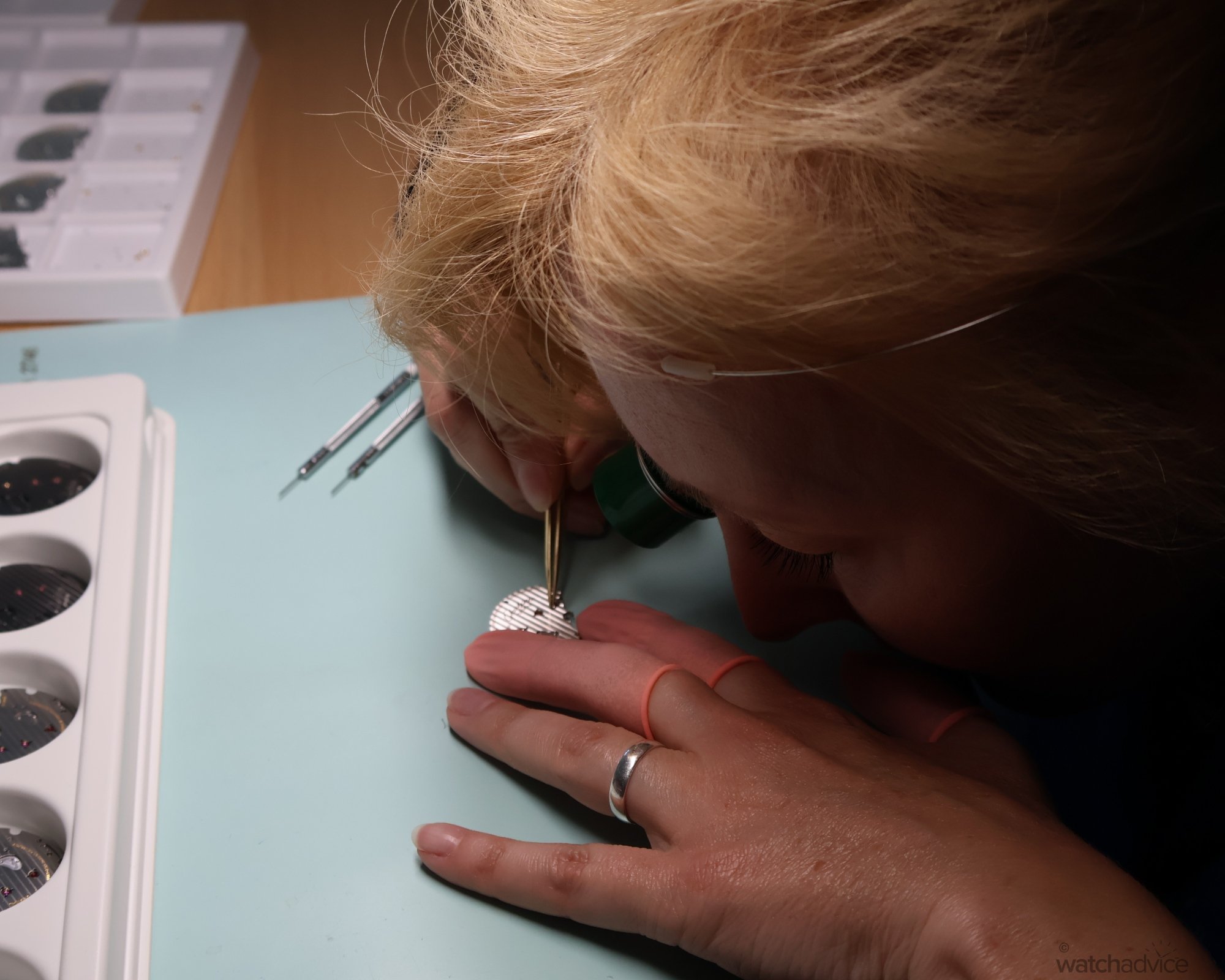

From there, we moved up to the finishing department. Along the way, I noticed the predominance of women in the workforce – something Ulrike highlighted as a point of pride not only for Glashütte Original but for the region as a whole. In the finishing department, I was greeted (in German) by a team of these highly skilled craftswomen.

Here, machined components are meticulously hand-finished. I saw parts before and after galvanic treatment and eagerly watched as techniques like perlage, bevelling, polishing, and screw- and jewel-setting were carried out. I was even invited to try my hand at perlage and setting, though with predictably clumsy results. Now I know how Tyler from The Menu felt, but thankfully I didn’t do enough damage to affect the brand’s bottom line.

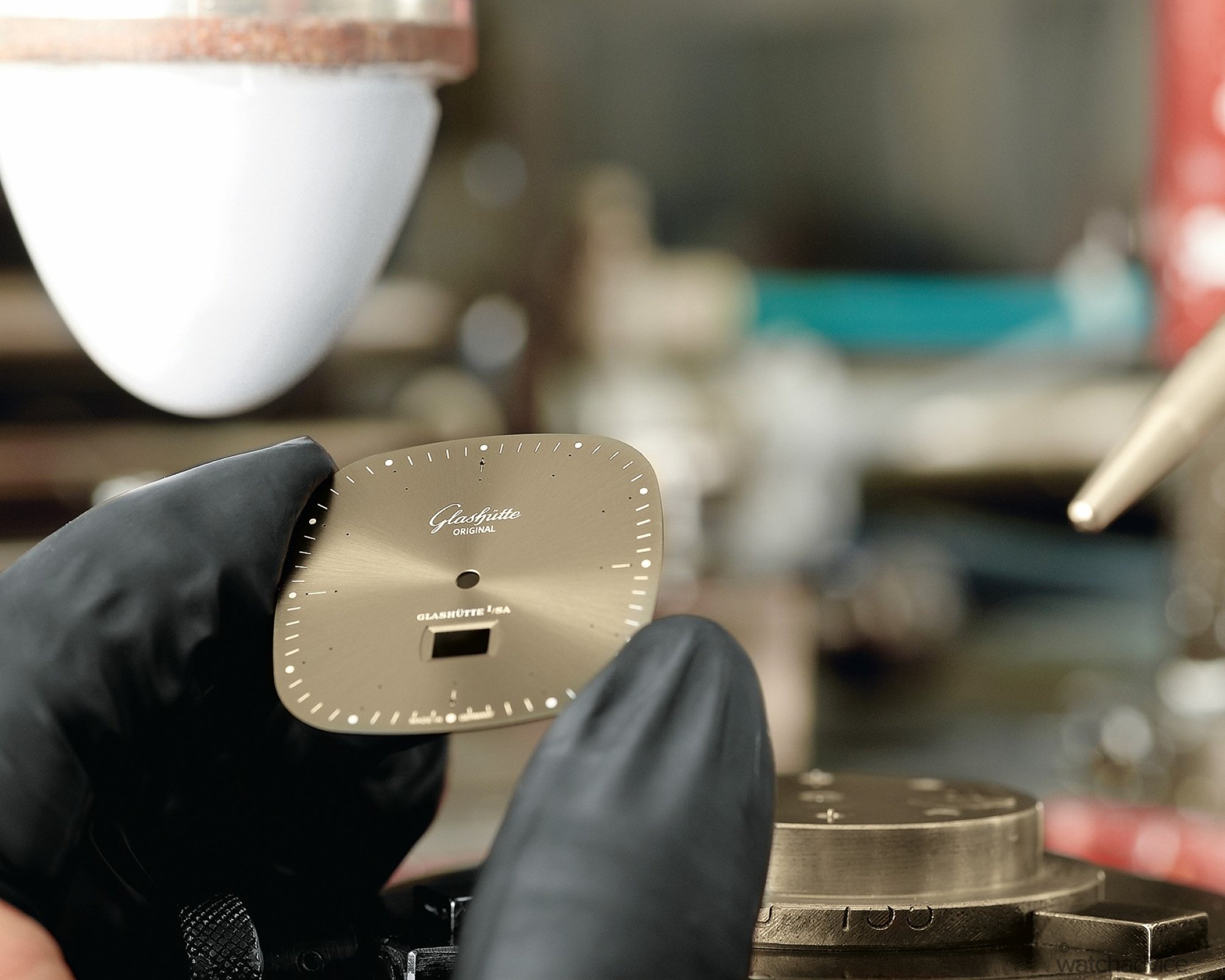

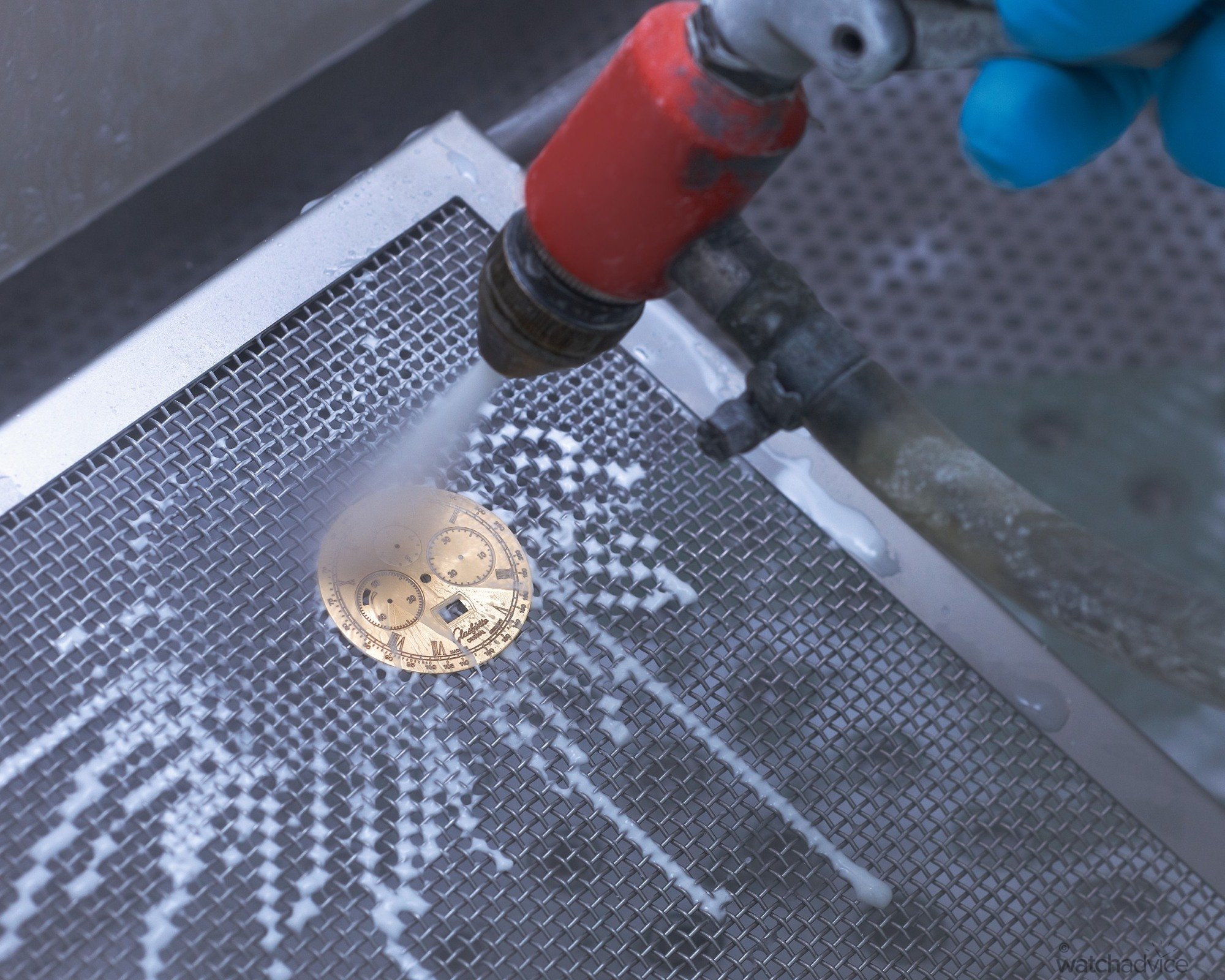

The final stage of the tour covered dial manufacturing, assembly and testing. Out of respect for the watchmakers’ concentration, I refrained from taking photos, but the experience spoke for itself. Glashütte Original’s commitment to producing nearly every component in-house was remarkable. Ulrike explained that dials were once manufactured in Pforzheim, a six-hour drive away near the French border, but in 2025 the facility was relocated to Glashütte itself. This move not only sped up the process, but also gave the brand complete oversight of production.

Although I couldn’t see every aspect of the operation, the insight I gained was still impressive. The level of care and precision invested in each part – from the smallest blued screw to final assembly – was overwhelming. Despite my tight schedule, the tour never felt rushed, and Ulrike was a consummate guide, making the mechanical heart of Glashütte Original come alive.

Day At The Museum

René, Ulrike and I soon sat down for lunch at the manufactory. I’m no foodie, but the meal was excellent and ended with a distinctly European dessert – Germknödel, if I recall correctly. Afterwards, Ulrike departed while René accompanied me to the watch museum.

A contemporary structure in the former mining town, Glashütte Original operates alongside several other German watch brands. Promotional material often mentions how close the watchmakers are to one another, and it’s no exaggeration; I was surprised by just how small Glashütte really is. The Glashütte Original building sits next door to A. Lange & Söhne, with NOMOS directly across the road, Tutima and Moritz Grossmann visible nearby, Kallinich Claeys to the north, and both Mühle Glashütte and Wempe further south.

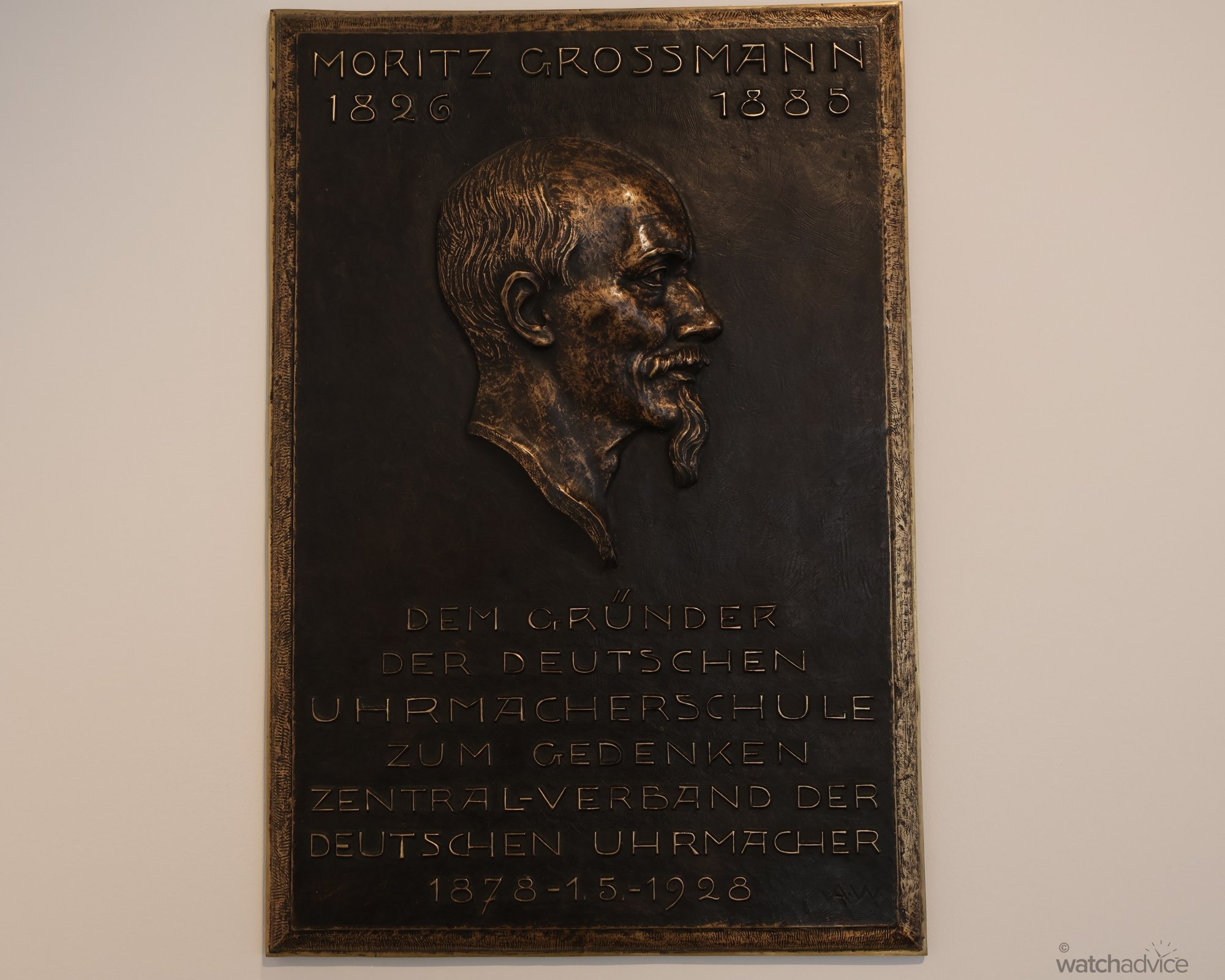

The founder of the German watchmaking school is commemorated by the Central Association of German Watchmakers.

At the museum, René took his leave, and I was welcomed by Katja Koch, a curator at the Deutsches Uhrenmuseum Glashütte (German Watch Museum Glashütte). This was the start of my second and final tour, where Katja guided me through the history of German watchmaking and its flourishing in Glashütte.

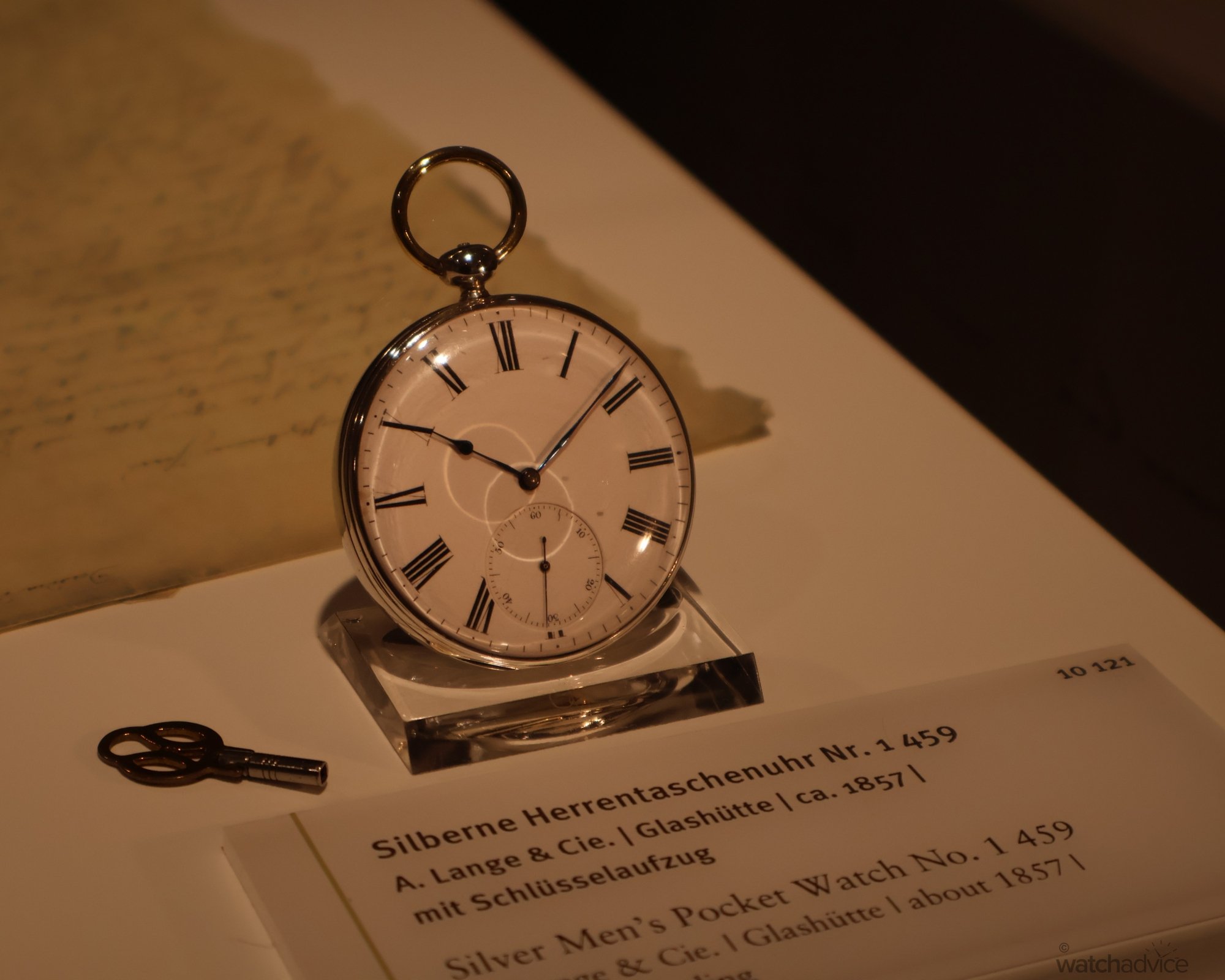

This is often where confusion arises. Although the brand we know as Glashütte Original was formally established in 1994, it represents a continuous line within German watchmaking history. The roots stretch back to 1845, when Ferdinand Adolph Lange, Moritz Grossmann, Adolf Schneider and Julius Assmann laid the foundations of the craft in the town. Grossmann would later establish the German School of Watchmaking, attracting a wave of remarkable independents, including Alfred Helwig – inventor of the flying tourbillon in 1921, a complication I hadn’t realised had German origins.

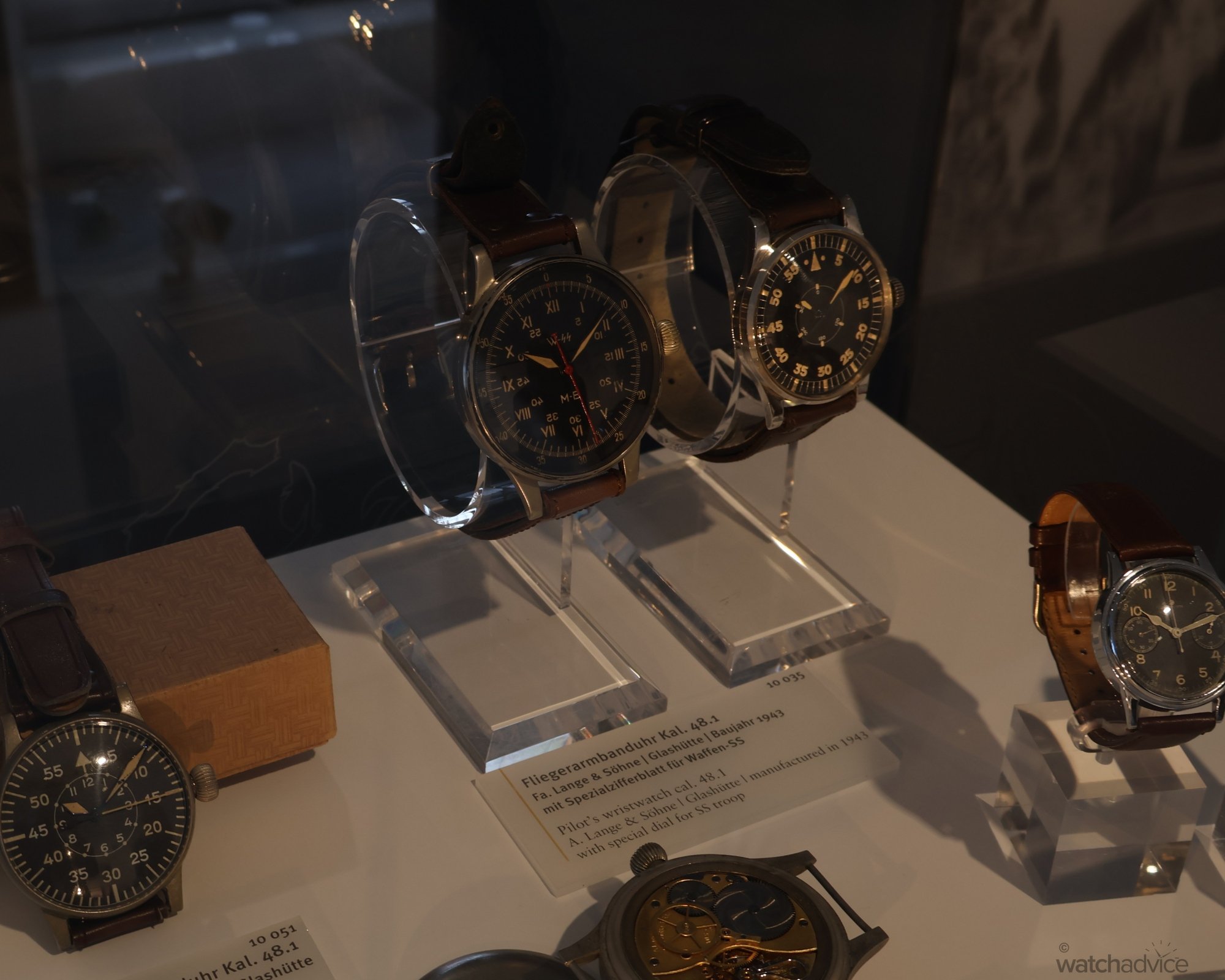

The 20th century, however, was marked by upheaval. Economic struggles after World War I and the destruction of World War II left the industry in turmoil. The Cold War compounded these difficulties, with the town’s watch production consolidated into VEB Glashütter Uhrenbetriebe (GUB) as part of East Germany. Yet even under state control, GUB continued to produce mechanical watches, largely insulated from the shifts of the Quartz Crisis – a small, silver lining within a dark cloud. Following German reunification, GUB was privatised, eventually becoming Glashütte Original and part of the Swatch Group. At the same time, brands such as Tutima and A. Lange & Söhne re-emerged, reclaiming their identities after decades behind the Iron Curtain.

The museum captures this rich history in impressive detail. Housed in what was once part of the German Watchmaking School founded by Grossmann, it presents not just the story of Glashütte Original but of every major contributor to the town’s horological tradition. While Glashütte Original and the Swatch Group – along with the mayor of Glashütte – played a central role in establishing the museum, its exhibitions honour the entire spectrum of German watchmaking.

Final Thoughts

Circumstances have often kept me from visiting the world’s horological hotbeds. While my enthusiasm lets me admire any watch – regardless of accessibility – my time at the Glashütte Original manufacture and museum was among my first true behind-the-scenes experiences.

It’s remarkable that a town of just seven thousand holds one of the densest concentrations of horological influence on the planet. For anyone seeking to learn an immense amount about watchmaking in a short time, Glashütte is unrivalled. Stories for another day, perhaps – but I can’t recommend a visit highly enough.

As my driver returned me to Dresden, I reflected on the gratitude I felt for such a remarkable experience. Katja, René, Ulrike and the entire Glashütte Original team were welcoming, generous with their knowledge and ensured the visit is one I’ll remember for a long time – at least until my inevitable return.