In a world that often prioritises speed and efficiency, A. Lange & Söhne takes a different path. Every watch is a reflection of time, care, and true craftsmanship. And it’s this mindset that sets them apart.

When you think of Fine ultra-high end watch making what are some of the first brand names names that come to mind? For me it would be watchmakers like Vacheron Constantin, Patek Philippe, Audemars Piguet, Jaeger-LeCoultre, Breguet and even independent watchmakers like Philippe Defour and F.P Journe. while there are certainly many other fine watchmakers There is 1. Other Brand that stands out for the exceptional craftsmanship: A. Lange & Söhne.

A. Lange & Söhne isn’t a watchmaker that tries to grab your attention with bold designs or heavy marketing. It’s a brand that doesn’t rely on influencers or celebrities to endorse its products. While this is certainly not a bad thing, it essentially means that they let their watches do the talking. This is a sentiment that is widely shared among collectors and enthusiasts, with A. Lange & Söhne being considered one of the best watchmakers in the world.

At first glance, most of A. Lange & Söhne’s collections feature a similar aesthetic, especially when it comes to case design. Bar the Zeitwerk and Odysseus collections, the brand’s core lines such as the Lange 1, Saxonia, 1815, and Richard Lange all feature a vintage-inspired aesthetic, with cases showcasing luxurious polished finishes, integrated lugs, and an overall beautifully elegant design. On a surface level, the watches can seem quite simple, with clean dials and classic proportions.

However, it’s when you truly get to spend time with them that you begin to notice the amount of detail and care taken in designing every element of the watch. And this is what the premise of this article is about. What sets A. Lange & Söhne apart from other watchmakers isn’t just their finishing or the integration of complications, but more the philosophy behind how each watch is made, and how it’s about doing things right, even when it’s not easy.

The Comeback Story

Before we delve into this philosophy further, it’s important to have a look at the history of the brand and how it came about in setting such a high standard for itself when creating these timepieces.

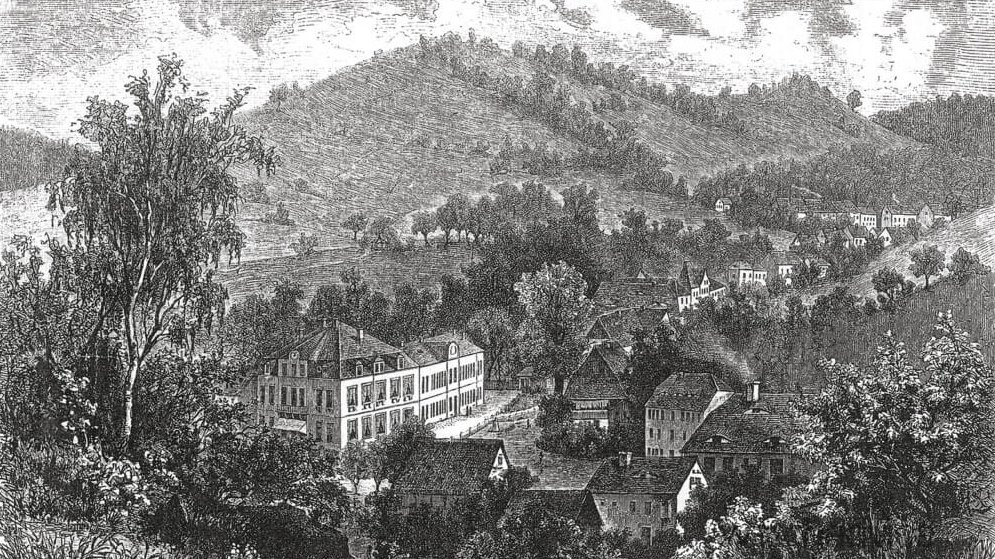

The story of A. Lange & Söhne first began in 1845 in the town of Glashütte, Germany. It was founded by Ferdinand Adolph Lange, who created his first watchmaking workshop in this small German town. At the same time, Glashütte was a struggling mining town. Ferdinand Adolph Lange’s vision was not just to create watches, but also to help the economy of Glashütte and put it on the map as a centre for watchmaking.

Lange received help from the local Saxon government, which enabled him to train local workers in the art of watchmaking. This, in turn, led to the establishment of a network of specialised suppliers, similar to what was happening in Switzerland, where farmers became trained in producing specific parts for movements. This endeavour would go on to form the foundation of what is essentially German watchmaking today.

The strive for perfection is linked with the Saxon mentality, where only the best was considered good enough. Other works, such as the sustainably promoted art and science in the region, were held to a very high standard, with this mindset becoming a key pillar for watchmaking. However, this was only the initial flame for the pursuit of perfection at A. Lange & Söhne.

Only 15 years old at the time, a young Ferdinand Adolph Lange took on an apprenticeship as a watchmaker, with his mentor being the highly skilled Johann Friedrich Gutkaes, whose reputation extended far beyond Saxony’s borders. After Lange completed his apprenticeship, he travelled through France, England, and Switzerland, gaining as much knowledge and experience in the world of horology as he possibly could. After this, he returned to Saxony, his beloved home, with the idea of turning the region into a watchmaking powerhouse.

This is where the true pursuit of perfection begins. With Ferdinand Adolph Lange’s extensive travels and experience, he set out to build watches that were among the best in the world. His efforts were quickly rewarded and recognised internationally, with his exceptional pocket watch designs presented as exquisite luxury gifts by heads of state.

Alongside his focus on craftsmanship, Ferdinand Adolph Lange was also obsessed with precision and quality, continually improving the accuracy of his pocket watches through better engineering and movement construction. These high-precision pocket watches that Lange developed were so accurate at the time that they were supplied to scientific institutions, observatories, and, as previously mentioned, royalty.

Over the next few decades, A. Lange & Söhne continued to grow under the Lange family name, with different generations of highly skilled watchmakers and visionaries refining what Ferdinand Adolph Lange had set in motion. The extremely high standards of finishing and construction never wavered, even through different hands of ownership, emphasising that this has always been one of the driving forces behind A. Lange & Söhne.

Then, as you know, came the Second World War, and the region of Saxony fell under Soviet control. In 1948, A. Lange & Söhne was nationalised, which sadly brought the company name to an end. Almost four decades went by where the A. Lange & Söhne name disappeared from watchmaking altogether, along with many other watch manufacturers in the Glashütte region.

While the story of A. Lange & Söhne could have ended there, it was only the beginning of a new chapter, one led by Walter Lange, the great-grandson of Ferdinand Adolph Lange. Following the reunification of Germany, Walter Lange revived A. Lange & Söhne in 1990 and brought the company back to life with four new models in 1994, including the iconic Lange 1. Walter Lange didn’t want to create timepieces as a quick release for the modern revival; instead, he spent a good four years carefully crafting watches that reflected A. Lange & Söhne’s philosophy of high watchmaking and expert craftsmanship.

Arguably, the most defining moment of the modern revival came in 1999 with the release of the Datograph. This chronograph timepiece from A. Lange & Söhne shocked the Swiss watch industry with its impressive technical complexity and outstanding movement finishing, qualities that we have come to know and admire to this day. Through the release of the Datograph, A. Lange & Söhne was firmly placed back among the world’s leading high-end watch manufacturers once again.

Doing Things The Hard Way

With a bit of insight into the backstory of A. Lange & Söhne, we can start to understand where the dedication to craftsmanship, high-precision movements, and fine watchmaking first began. This all stems from one philosophy that lies at the heart of A. Lange & Söhne: doing things properly, rather than doing what is easy.

In the watchmaking industry, many brands prioritise efficiency and scalability. However, A. Lange & Söhne takes a very different approach, where every decision in the watchmaking process, from movement design and construction to its finishing, is driven by quality rather than convenience or speed of manufacture. This, of course, leads to a far more complex manufacturing process, one that is built around time-consuming methods even when simpler alternatives exist. But alas, this is what sets A. Lange & Söhne apart.

This same philosophy of “going the extra mile” is also applied to how the movements are constructed and assembled. In case you didn’t know, one of the other defining qualities of A. Lange & Söhne is their double assembly of the movement. Lange is famously known for this double assembly process, where, regardless of the type of movement, each one is first assembled, taken apart, cleaned, and then reassembled again.

This is certainly the more demanding way of manufacturing a watch, as it almost doubles the time required in the process. However, what you get in return is that every component is finished and adjusted to the highest possible standard. This approach prioritises precision and perfection over efficiency, and honestly, if you’ve ever held an A. Lange & Söhne timepiece in your hand, you would understand and see exactly why.

Craftsmanship That Goes Beyond Visibility

One of the things that stands out about A. Lange & Söhne for me, and I would dare say for a majority of enthusiasts, is the finishing of the movements. As the brand puts it, “It can be quite easy to identify an A. Lange & Söhne movement at first sight.”

Each individual component is decorated with its own specific type of finish, and even though some of these components may not be visible through the sapphire crystal caseback, no matter the size of the movement, each part must comply with the level of artisanal and aesthetic standards set by A. Lange & Söhne.

A. Lange & Söhne states that “It takes several months of practice just to perfectly execute a flat polished finish, while in chamfering, great emphasis is placed on assuring that the edges are not only bevelled to the same angle but also to the same width. A special type of finish is reserved for the balance cock: it is engraved with the Lange-style floral pattern that makes each Lange watch unique”.

The artisans at A. Lange & Söhne have an extensive range of finishing techniques at their disposal, including but not limited to:

Ribbing:

The ribbing finishing technique, where you see uniform stripes as decoration on for example the three-quarter plates and the bridges, is a common occurrence on Lange calibres. These stripes are created using a slightly inclined rotating grinding wheel, which is then guided along the component in straight, parallel lines.

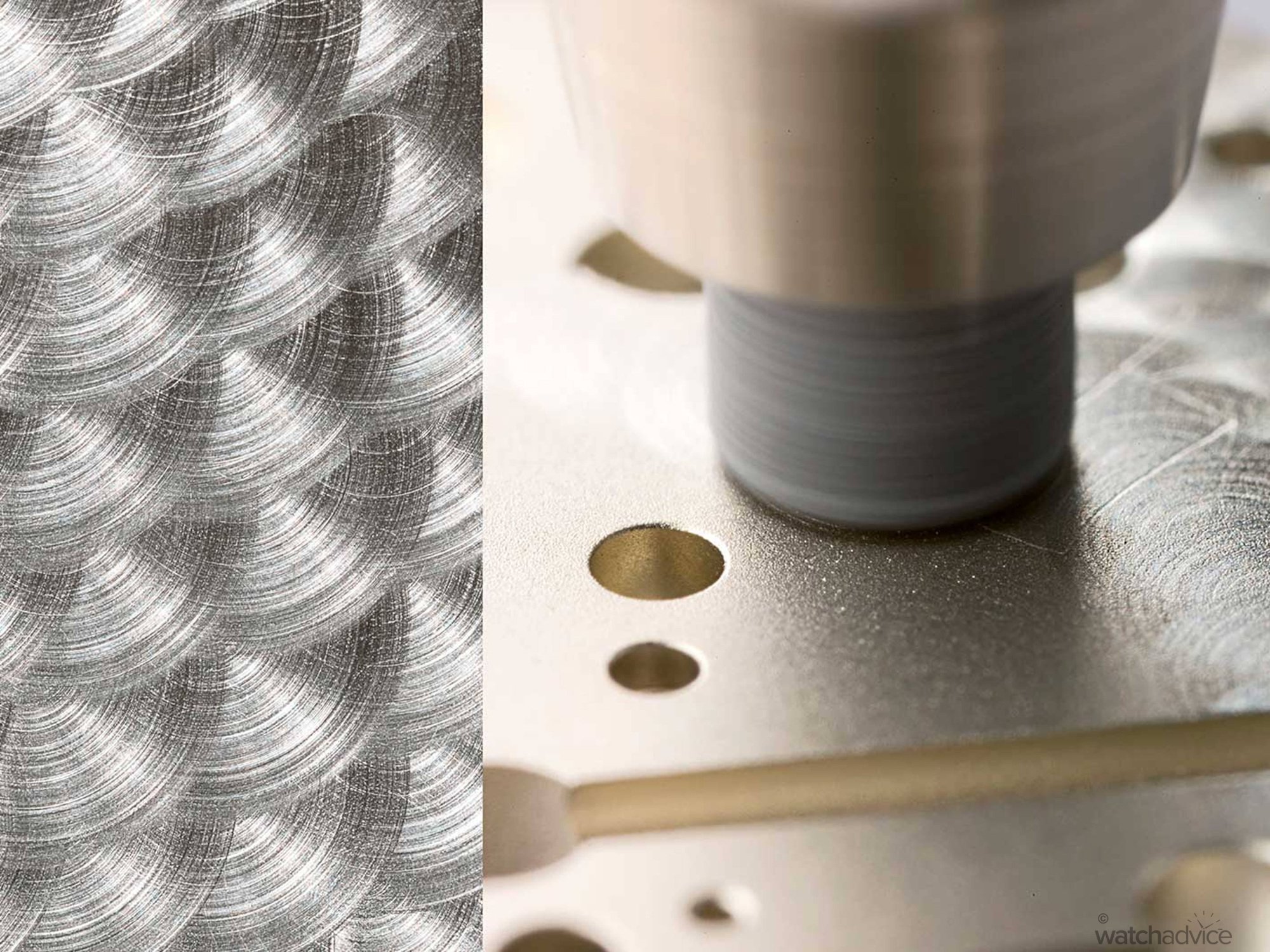

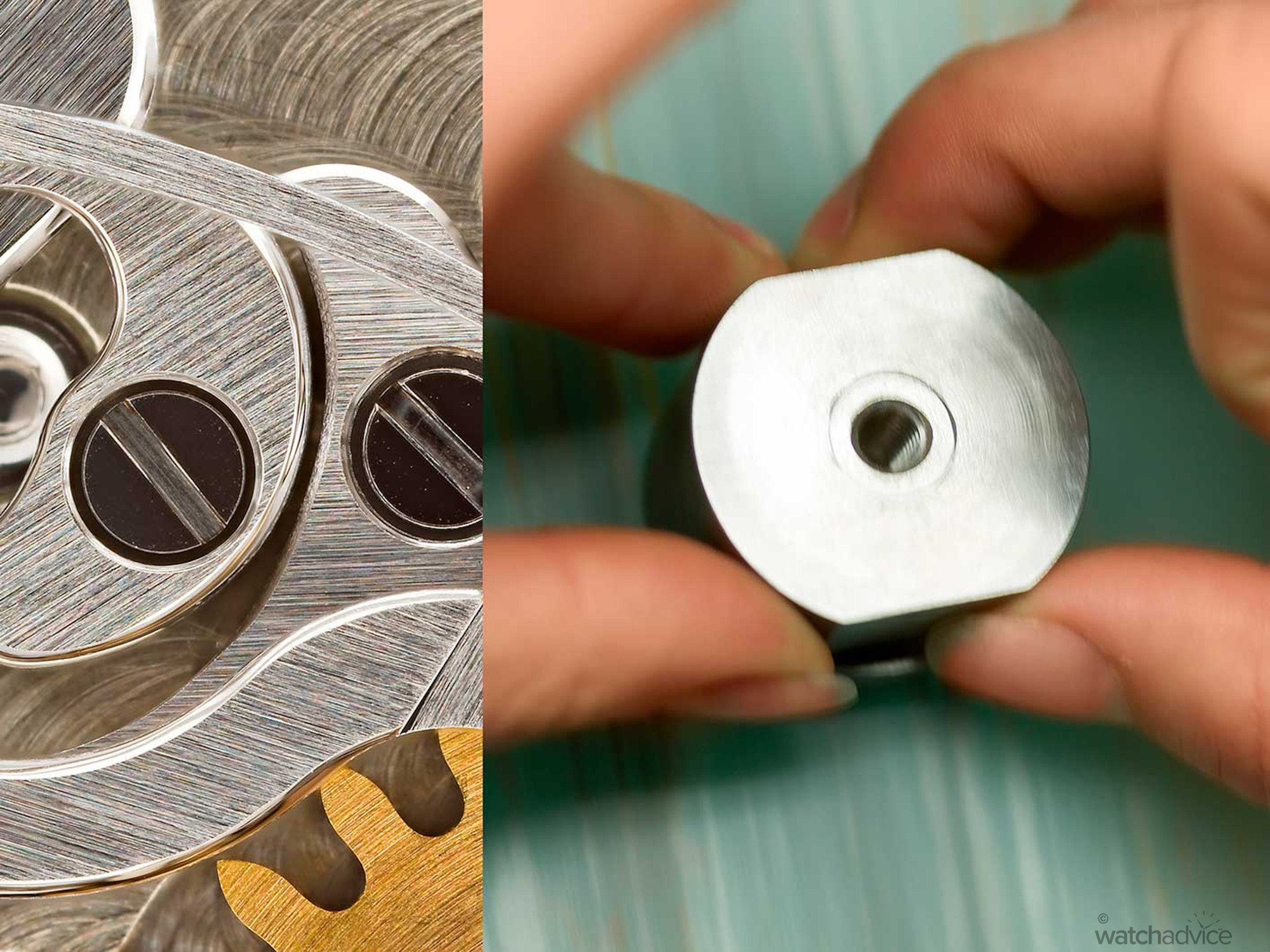

Solarisation:

One of the most stunning finishing techniques, solarisation, is a decorative finish that is mainly applied to mainspring barrels and other larger round surfaces or wheels in A. Lange & Söhne’s movements. This particular finishing method is created by rotating the specific component, such as wheels or mainspring barrels, and grinding the surface in opposing directions.

Perlage:

One of the more common finishing techniques that we are all used to seeing is perlage. I even had the chance to try this finishing technique, and I can safely say it is certainly not as easy as it looks. The perlage finishing technique is a cloud-like decoration, created using a rotating abrasive that briefly stamps the specific component. Each perlage stamp overlaps the other, giving the appearance of a wave-like finish.

Chamfering:

Another more commonly found finishing technique in movements is chamfering. Chamfering is a process that involves both bevelling and polishing, and for A. Lange & Söhne, this technique is used on the edges of bridges and levers. A. Lange & Söhne takes this a step further, producing chamfers with a consistently uniform width and angle on virtually every edge in a movement that is finished using this technique.

Straight Graining:

Straight graining is a particular type of finish that is applied especially to steel springs, yokes, and clicks. To execute this type of finish, it is produced using abrasive paper running across the part, in a longitudinal direction. It is applied with careful movement to “assure that the delicate linear pattern is evenly applied to even the furthermost corners of the component.”

Circular Graining:

One of the more popular finishing techniques in the watchmaking world is circular graining. This is also specifically used for smaller wheels, and you can even see this finishing technique from other watch manufacturers, sometimes on sub-counters on the dial side. The regular circular contours are produced when the part is rotated on abrasive paper.

Circumferential Graining:

Circumferential graining is applied specifically to the vertical edges of the frame elements of A. Lange & Söhne’s movements. This finishing technique is executed by using a rotating abrasive peg, whereby the component is pressed against the side of the peg to achieve the desired textured finish.

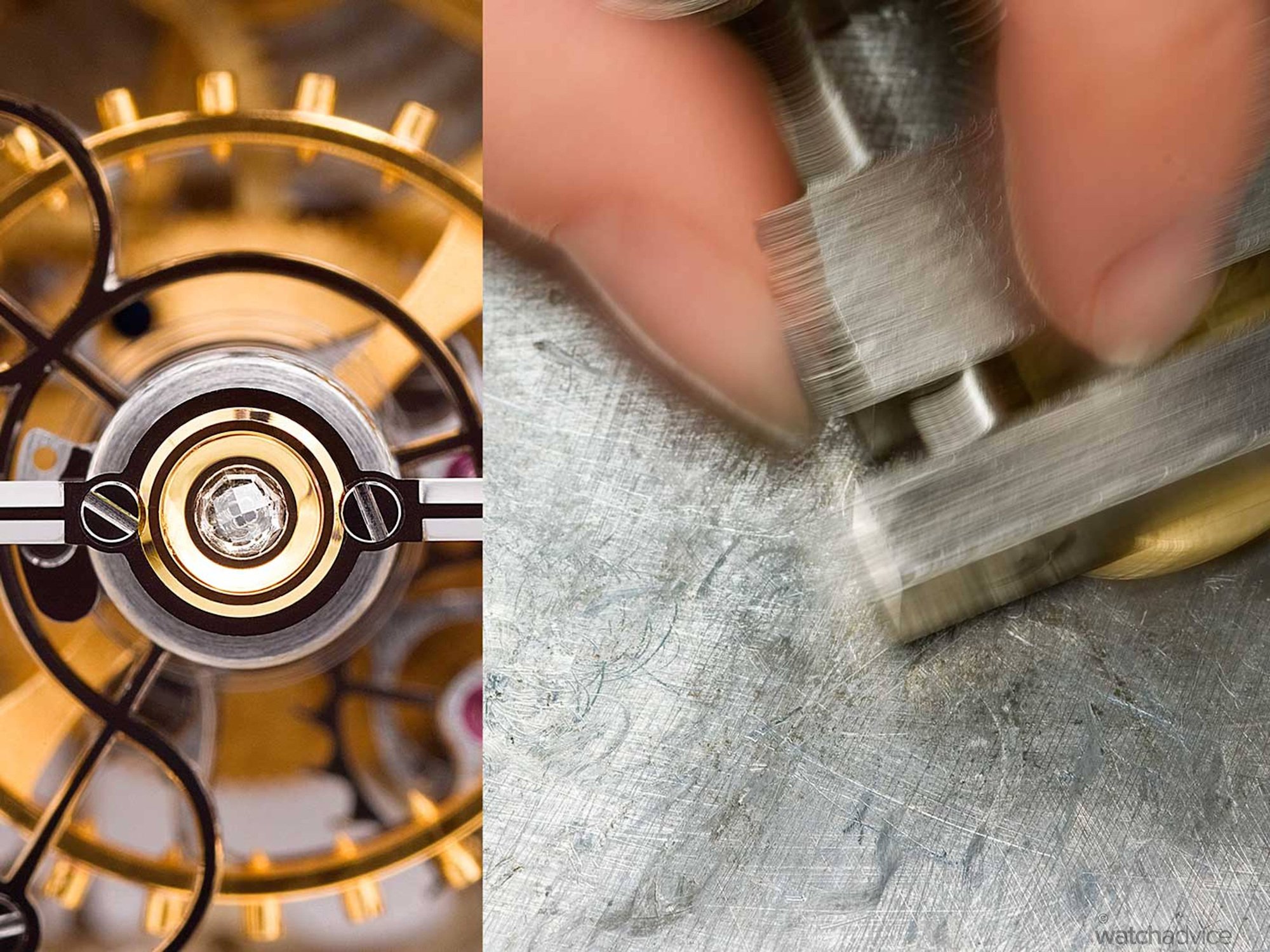

Flat Polishing:

Flat polishing is executed on components such as the hairspring, the end piece of an escape wheel, along with other various parts of the movement.A. Lange & Söhne states that states “Up to two hours of precision work are needed to mirror-polish these surfaces. To flat-polish a component, the finisseur presses it into the pith of an elderberry shoot and guides it in figures of eight on films coated with progressively finer diamond powder. This process requires the utmost in concentration. Even a tiny grain of dust between the part and the polishing film, or excessive pressure on the part, can wipe out hours of work in a second“.

Black Polishing:

Unlike flat polishing, the black polishing finishing technique is only carried out on a very few select parts of the movement. This is mainly due to the fact that black polishing can take several days to complete. A. Lange & Söhne states that “Using special abrasive pastes, the respective parts are manually polished on a tin plate until they appear to be black at a certain angle of incident light”.

Polishing of Internal Angles:

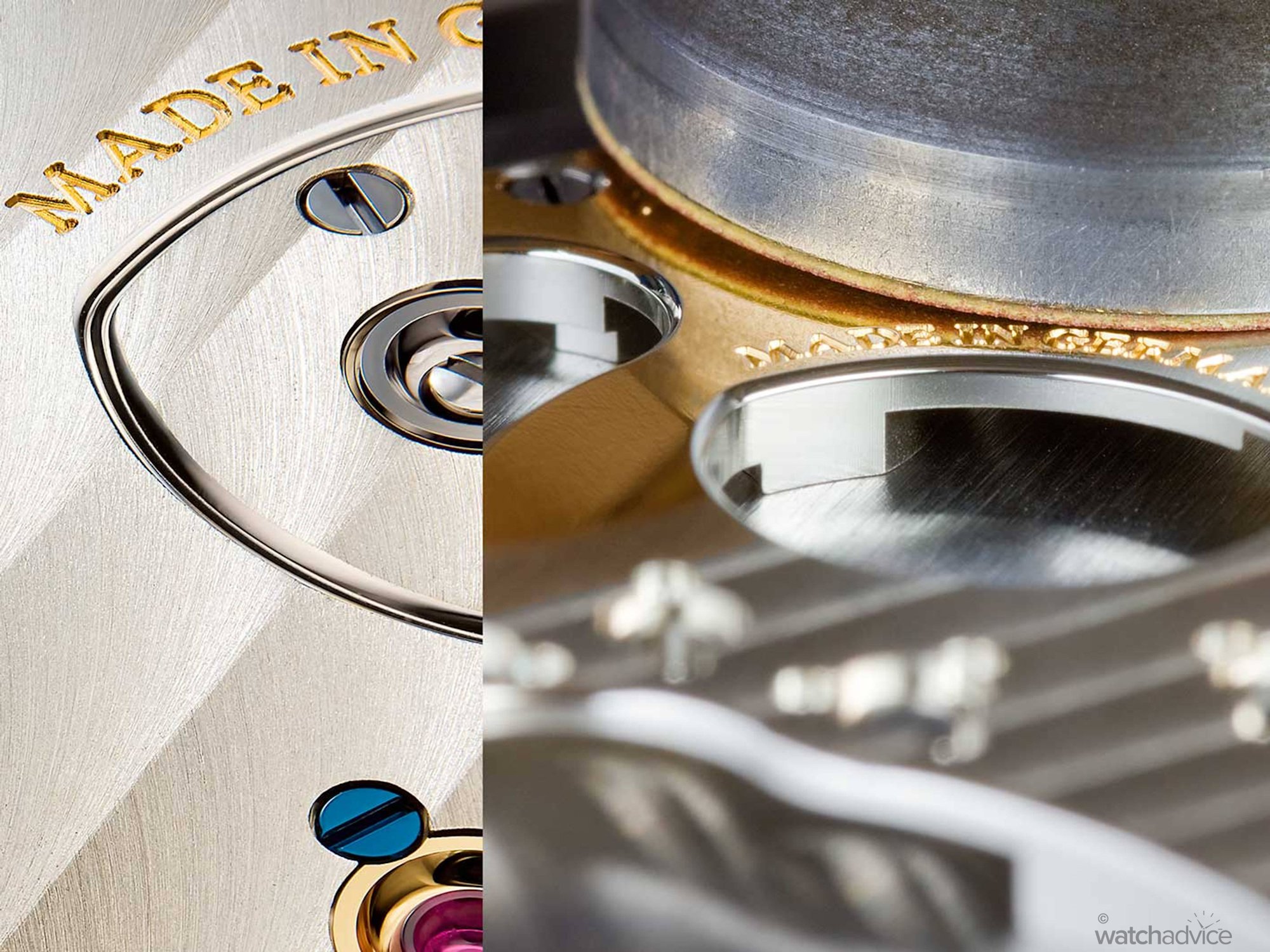

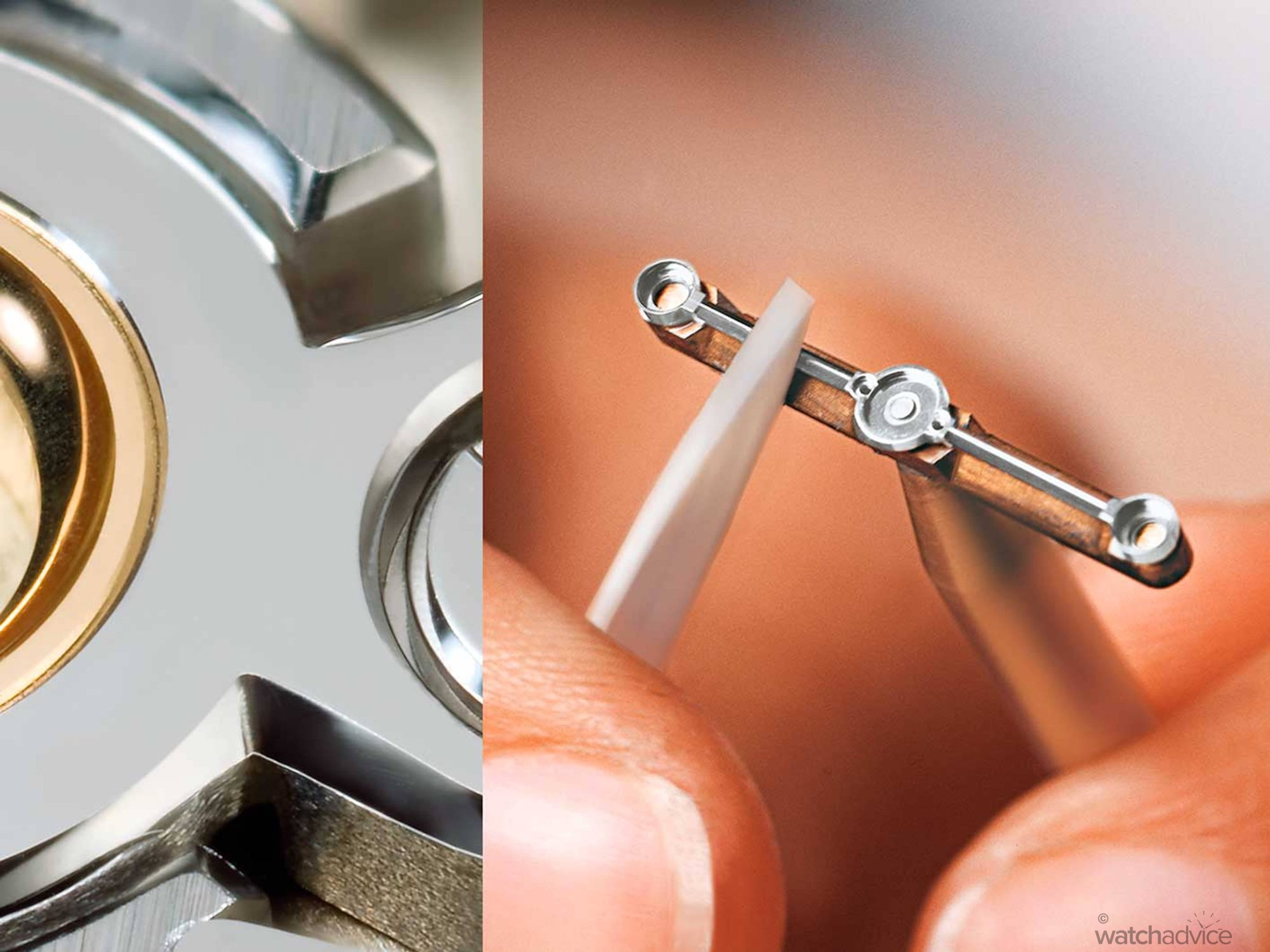

The polishing of internal angles is a technique that is found throughout the timepiece, not just in the movement, and is one that gives the watch a stunning shine, especially at different lighting angles. This is a technique A. Lange & Söhne takes very seriously, with a high degree of precision being emphasised in the process. It is one of the details that we often notice first in a highly finished watch, as the shine is something that immediately captures attention.

A. Lange & Söhne specifically states that there are two variations of this polishing technique. Firstly, if the internal angle is rounded, it is safe to assume that it has been machine finished. As you may have already figured out, A. Lange & Söhne prides itself on hand-finishing techniques, which means that the polishing of internal angles is precisely defined and straight, “because only a human hand can execute the linear polishing motion needed to obtain such a result.”

Hand-Engraved Balance Cocks:

While many of the aforementioned finishing techniques are common practice among high-end watch manufacturers, the way A. Lange & Söhne finishes the balance cock is quite unique to them. For several generations throughout A. Lange & Söhne’s history, the balance cock has featured a distinctive motif. It consists of flower petals surrounding the central screw of the cock, along with a floral pattern that subtly follows the characteristic outlines of the component to which it is applied.

However, as these balance cocks are finished by hand, each artisan’s engraving carries a unique signature. The depth of the cut and the curl of the lines can vary from one balance cock to another, setting each individual timepiece apart from the others.

Three-Quarter Plates

The three-quarter plate is Ferdinand Adolph Lange’s solution to the various interconnected components of the movement moving out of alignment when one single element needed to be corrected. The three-quarter plate is essentially an upper plate that accommodated all the pivots of the most important wheels and bearings.

A. Lange & Söhne state that “this approach significantly accelerated the assembly process, although particular skill was needed to simultaneously “steer” all arbors into their bores on the underside of the plate. During a period of nearly 20 years, Lange kept refining the design of this plate.”

In modern day watchmaking, A. Lange & Söhne is manufacturing the three-quarter plate using untreated German silver, an alloy containing copper, nickel and zinc. This material was chosen for its high stability and resistance to corrosion. In the course of time, it takes on a protective, gold-yellow patina and does not require any electrolytic anti-corrosive coating.

What makes A. Lange & Söhne stand out is that not only are the components visible through the caseback finished to an incredibly high standard, but the same level of detail and care is also applied to areas of the movement that sit beneath the dial, components that are hidden from view once the watch is fully assembled.

This is an approach that reflects a much deeper commitment to craftsmanship, showing us that A. Lange & Söhne cares about quality, even when it’s not directly visible to the wearer. Every component is treated with the same level of importance, with the end result being a level of consistency that is rarely found, even among high-end watchmakers.

The Double Assembly

A. Lange & Söhne put it best “The watchmakers in Saxony have but one goal: the perfect timepiece.”

As we have already seen, Saxon watchmaking is not one that is going to compromise on quality over efficiency. With every component of the movement being finished to a high degree of detail and execution, it leaves the assembly process to ensure everything is put together smoothly and runs as accurately as designed. One of the consequences of an assembly process that ensures such a high level of quality is that the movement is assembled twice.

For A. Lange & Söhne, it makes no difference whether the movement is a simple three-hand calibre or features complications such as a chronograph, or even more intricate mechanisms like minute repeaters and tourbillons. There is a carefully thought-out process and a valid reason for A. Lange & Söhne to apply a double assembly to all of their movements. One primary reason is the use of German silver, especially for the three-quarter plate.

This material is highly sensitive and can tarnish easily, hence why extreme care must be taken in its placement of the movement, leading to one of the reasons why A. Lange & Söhne does a ‘trial run’ of the movement fitting process. It is not simply a case of fitting all the components together, taking them apart, and then doing so again just for the sake of ensuring that all components fit within their necessary tolerances and operates smoothly.

Initial Assembly Process

A. Lange & Söhne does not rush the assembly process, with many hours invested into each movement to ensure each watchmaker gets the details right. The complex assembly process begins with the watchmaker fitting all the components together initially, ensuring that all the parts fit together perfectly and that the movement is “operational.”

The watchmaker uses “jig screws” instead of blued screws during the initial assembly. The reason is that these thermally blued screws serve as a visual finishing touch, and if they were constantly tightened and unscrewed, the screw heads could become scratched, the slots could wear out, and the blue finish could also become damaged.

Once the initial assembly is complete and the watchmaker is satisfied with all components, all the parts are painstakingly disassembled and cleaned. The components then go through the decorative or finishing process using the techniques outlined above. This, as previously mentioned, includes parts that are never seen by the wearer. The “jig screws” are then replaced with the final thermally blued screws.

The Final Re-assembly

Before the second assembly begins, the signature three-quarter plate, introduced by Ferdinand A. Lange in 1864, is decorated with the characteristic Glashütte ribbing. The gold chatons, in which the jewels sit, are mirror polished, marking the final step before the watchmaker once again assembles the movement. The final assembly includes carefully lubricating the movement at over 50 oil sinks and bearing points with up to eight different greases and oils.

This double-assembly process not only ensures the quality of the movement, but also preserves the finishing of the components in an almost pristine condition. If the components were individually finished before the first assembly process, there is a high chance that minute scratches could occur during disassembly and the final construction of the movement.

This is obviously a much more complex approach to watchmaking, taking almost double the time for assembly. While this process may seem daunting even for a simple three-hander movement, imagine the watchmaker having to work on one of the more complex Lange calibres.

Movements like the one in the Richard Lange Tourbillon “Pour le Mérite”, which consists of 84 parts just for the tourbillon alone, already highlight the level of complexity involved. Now consider applying the same double-assembly process to some of A. Lange & Söhne’s grand complications, where the number of components increases significantly. You truly begin to understand the painstaking double-assembly craftsmanship these watchmakers go through in order for the wearer to enjoy what is worn on the wrist.

The Peak Of A. Lange & Söhne Craftsmanship: The Handwerkskunst Editions

The standard timepieces we are used to seeing from A. Lange & Söhne already showcase an incredibly high level of watchmaking, from perfectly proportioned case sizes and carefully considered dial designs to movements finished to the utmost quality, delivering a truly striking visual impact.

But have you ever wondered what would happen if all of this was taken to another level? Could A. Lange & Söhne outdo itself in the processes and standards it has set, to achieve an even higher level of finishing and execution? The Handwerkskunst Editions were created for exactly this reason. Like many other high-end watchmakers and their platforms for experimental creations, the Handwerkskunst Editions are where A. Lange & Söhne can truly push boundaries and achieve what I believe is the pinnacle of watch finishing.

Introduced in 2011, the Handwerkskunst collection, translating to “craftsmanship” in German, represents A. Lange & Söhne’s highest expression of artisanal craftsmanship. These timepieces, created to an incredibly high standard, are not designed to showcase new complications, but rather to elevate traditional decorative techniques to the highest possible level.

A. Lange & Söhne takes existing models from its collection and elevates them through the Handwerkskunst series, with each timepiece produced in extremely limited numbers, often just a handful of pieces, making them some of the rarest Lange creations. With a significantly higher level of craftsmanship being applied compared to what we are used to seeing from the manufacture, this comes at the cost of the time and manual effort required to achieve such a finish.

There are currently eight limited edition models in the Handwerkskunst collection, with each one finished to an extremely high standard using traditional, hand-executed decorative techniques that are carefully tailored to each individual timepiece, further enhancing its design.

My two personal favourite models are the Richard Lange Tourbillon “Pour le Mérite” Handwerkskunst and the 1815 Rattrapante Perpetual Calendar Handwerkskunst. Both base models already showcase impressive technical flair combined with beautifully executed finishing, but what A. Lange & Söhne has done to elevate these pieces goes even further.

What immediately stands out are the patterned and textured dials, with the Richard Lange Tourbillon featuring a grained dial that is colour matched to the Honeygold case, while the 1815 Rattrapante presents a starry motif dial that beautifully complements the moonphase complication.

Beyond the dial re-creations, the Handwerkskunst editions take engraving, finishing, and decorative techniques far beyond what is typically seen from A. Lange & Söhne. In many ways, these pieces represent the purest expression of the brand’s philosophy. They are not created to be efficient or widely produced, but to showcase what is possible when time, skill, and craftsmanship are given complete freedom.

Built on Principles, Not Compromise

A. Lange & Söhne is one brand that doesn’t chase trends or attention. It quietly goes about building a reputation centred around a clear and consistent philosophy. And that philosophy? It’s about doing things properly, rather than doing what is easy or efficient.

This is the approach A. Lange & Söhne has taken to essentially every part of the manufacturing process. We can see, or, in some cases, not see, as it is hidden away, this in the intricate way the individual components of the movement are finished, even when these parts sit beneath the dial. It is a philosophy that has been instilled in the watchmaking process since A. Lange & Söhne’s beginnings, stemming from Saxony’s perfectionist mentality.

And as we have come to learn, it’s not just the finishing that the German watchmaker prides itself on, but also the assembly of its movements, or rather, the double assembly. It is a process that initially ensures all the parts are perfectly aligned and operating exactly as intended, before being disassembled to carry out the various traditional hand-finishing techniques on each individual component.

This is a process that, once the second and final assembly is carried out, ensures that the finishing and overall quality of the movement remain as pristine as possible. If you ever want to understand why some of A. Lange & Söhne’s timepieces command the prices they do, this is a clear indication, reflecting the time spent handcrafting each component, the level of care taken during assembly, and the unwavering commitment to getting every detail right.

In a world that favours speed and efficiency, that commitment to doing things properly is what makes

A. Lange & Söhne truly stand apart.