As part of our commitment to bring Swiss Watchmaking into your loungeroom, we visited the Breitling Chronometrie in La Chaux-de-Fonds to see how the iconic watches are made.

When it comes to watchmaking, the process is similar at its core. Just like the internal combustion engine, the principles and theory are the same no matter what brand you think of. However, each is very different in how they approach it, and the same goes for watchmaking. This is true when it comes to the design of the movements themselves, and how they are assembled and cased up into the final product you and I see, buy and wear. So based on that thinking, you could be mistaken in thinking that all watch Manufactures are the same – but you would be wrong!

Each time I, and the other team members from Watch Advice visit a Manufacture, we’re always surprised at just how different each brand is. Yes, there are milling machines, watchmakers, decorators, etc, but this is where the majority of similarities stop. Each Manufacture has its own way, its own set-up, processes, and of course, environment where the work is done. Some are still on the same site they were over a hundred years ago, with updates and extensions to the buildings as time has gone by, and some have brand new Manufactures with the state-of-the-art technology throughout. And each Manufacture seems to fit the brand well. You walk in and say, “Yeah, this feels like (inert brand here)”.

So on an unusually rather chilly Swiss morning for the time of year it was, we were picked up to visit our latest Manufacture, and it is one I had been looking forward to for a while – The Breitling Chronometrie in La Chaux-de-Fonds in the heart of the watchmaking valley.

Situated where many brands are, La Chaux-de-Fonds is about an hour and a bit outside of Geneva in the Swiss Jura. Like much of regional Switzerland, the country is rolling hills, green pastures and little towns dotted along the way between major towns like La Chaux-de-Fonds. For Breitling, this isn’t the original factory set up by Leon Breitling on Rue de Montbrilliant, but a new (ish) facility on the outskirts of town, not far from the likes of TAG Heuer and Cartier.

So, in 2001, Breitling opened its new factory in the current location, but, even though it was a state-of-the-art facility, the growing brand needed to expand it just eight years later, thanks to growing demand as well as a need to develop its own in-house calibre. So in 2009, it was officially opened and is what you see today. What sets Breitling apart from other Manufactures? Well, in my opinion, it is two aspects. The first being it is very on brand. You walk into the entry and you instantly know it is Breitling thanks to the decor, thematics and design style that is similar to that found in Breitling Boutiques around the world. For other Manufactures, inside they can be a little non-descript, with very little to suggest what brand it is, other than some branded signs and obviously the watches being made. Breitling, however, is full of memorabilia, nods to the brand’s heritage and associations with motorsport, the aeronautical industry, surfing and diving etc.

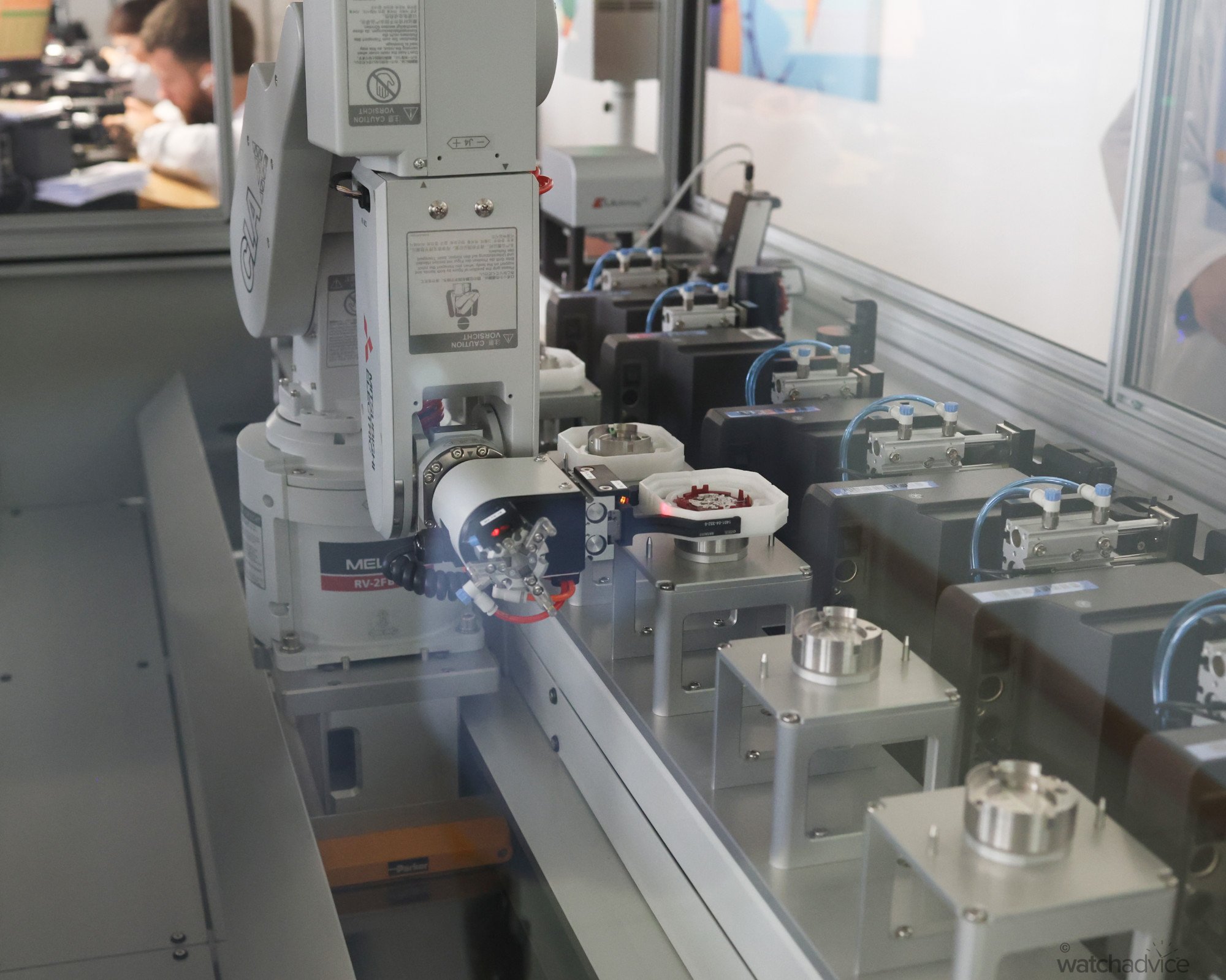

The second aspect that sets the Chronometrie apart is the way Breitling makes its watches, and one thing they are quite proud of – the amalgamation of technology, automation and human craftsmanship. When the Manufacture expanded in 2009, it had to do so as it needed to develop its own in-house calibre, the B01. With 346 individual components, which are combined into 76 elements and 41 screws, it was decided that man and machine would need to work together to deliver the best possible movement, each one COSC certified. So the 346 parts are assembled into the 76 elements by machine, some of which check and test tolerances down to one thousandths of a millimetre, as well as administer lubrication to certain parts more accurately and precisely than a human can.

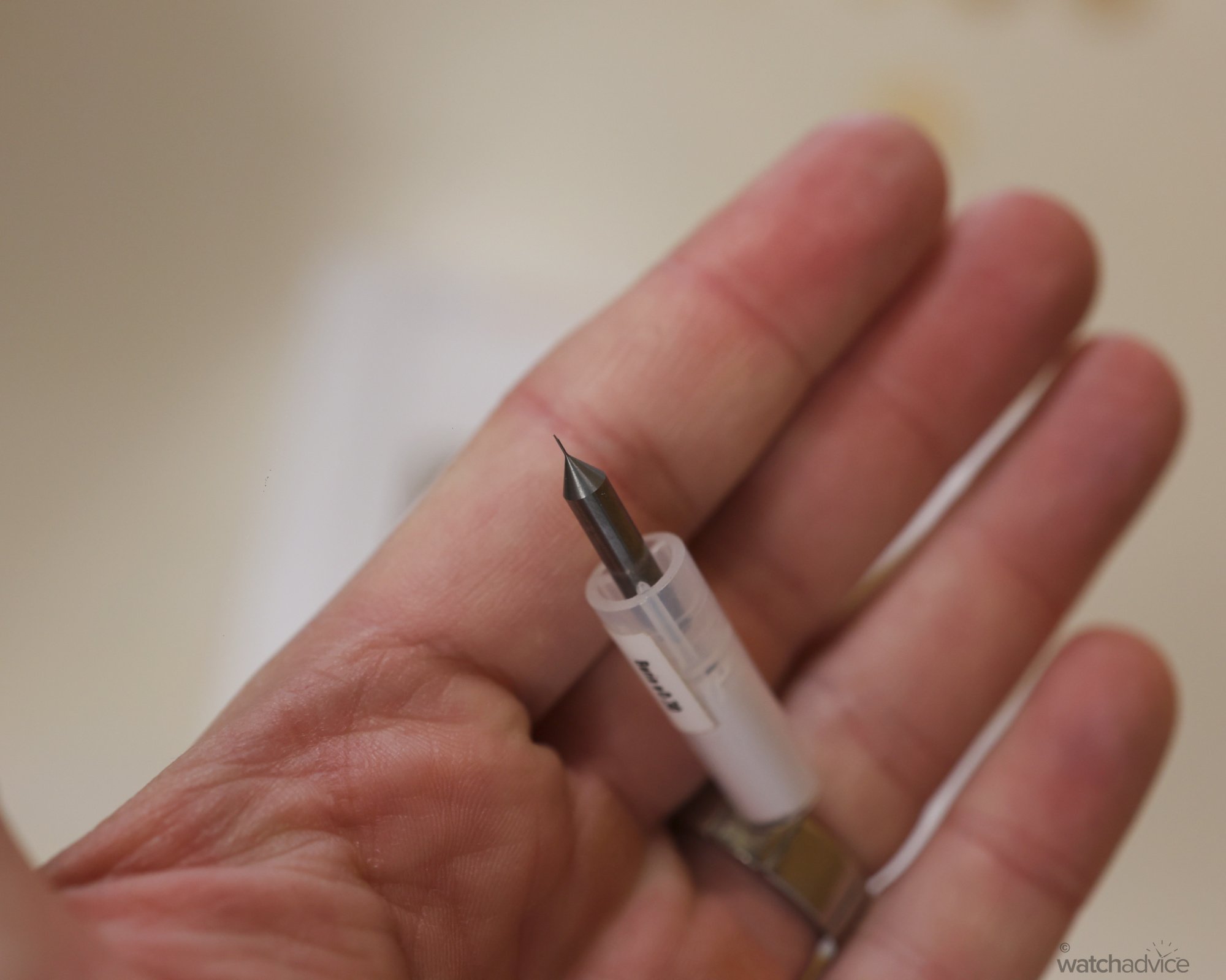

These are then all assembled by hand, with many steps done by the skilled watchmakers, like boring the holes for the balance wheel, a skill that takes years to master and is only entrusted to the human hands in charge. This is all done to create a better way to make watches, more efficiently and with fewer errors. Makes sense to me. So, with that little bit of a prelude and backstory done, let’s take a walk through the Breitling Chronometrie as we saw it…

Milling, Machining And Boring

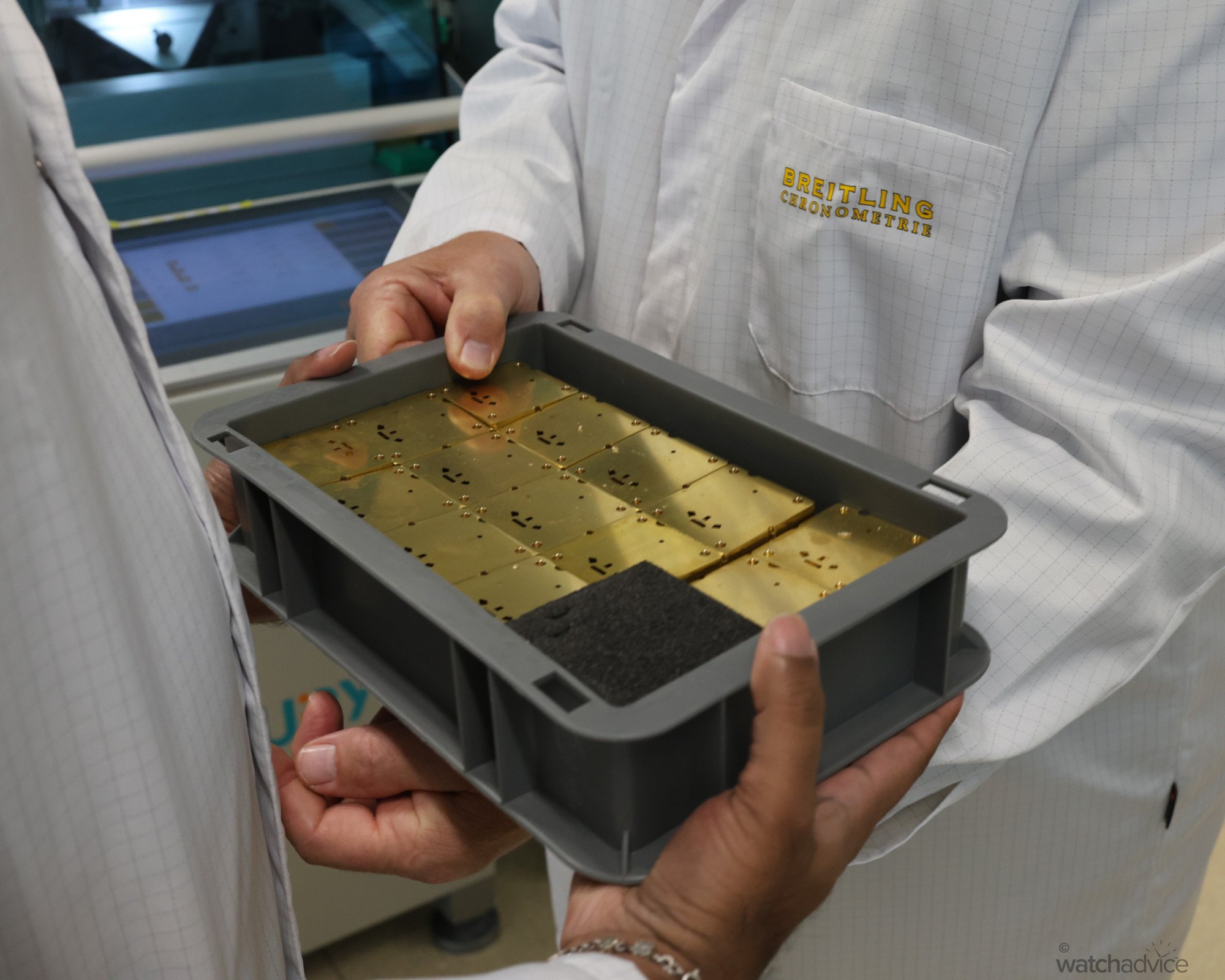

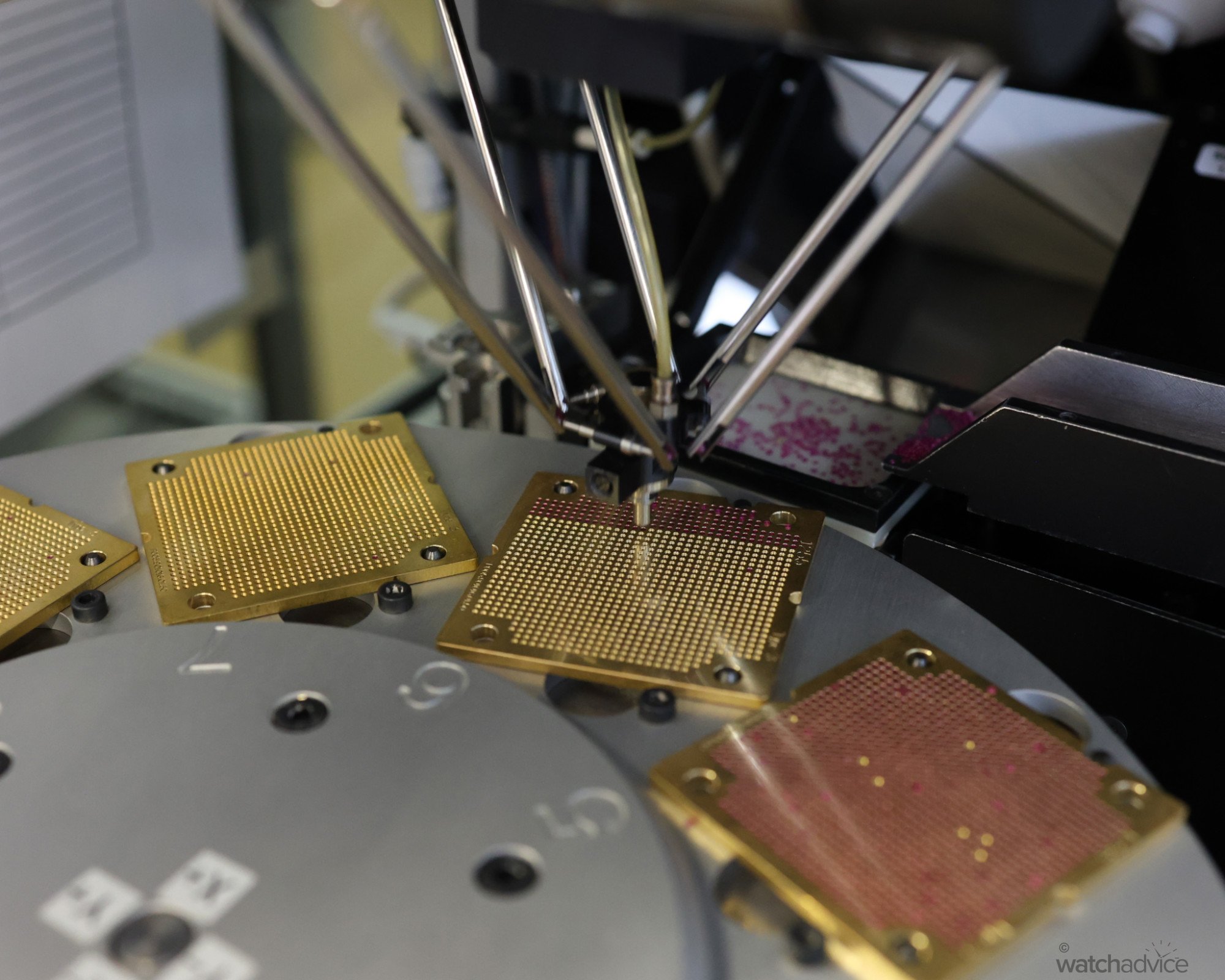

Like any watch Manufacture, it all starts with milling the major and larger components of the movements. This is where the base plates and bridges are made. These are made from whole bits of brass, all cut into square plates to start with. Individually, they don’t weigh much, but hundreds together take a little to lift. Who needs a gym when you can move brass plates around?

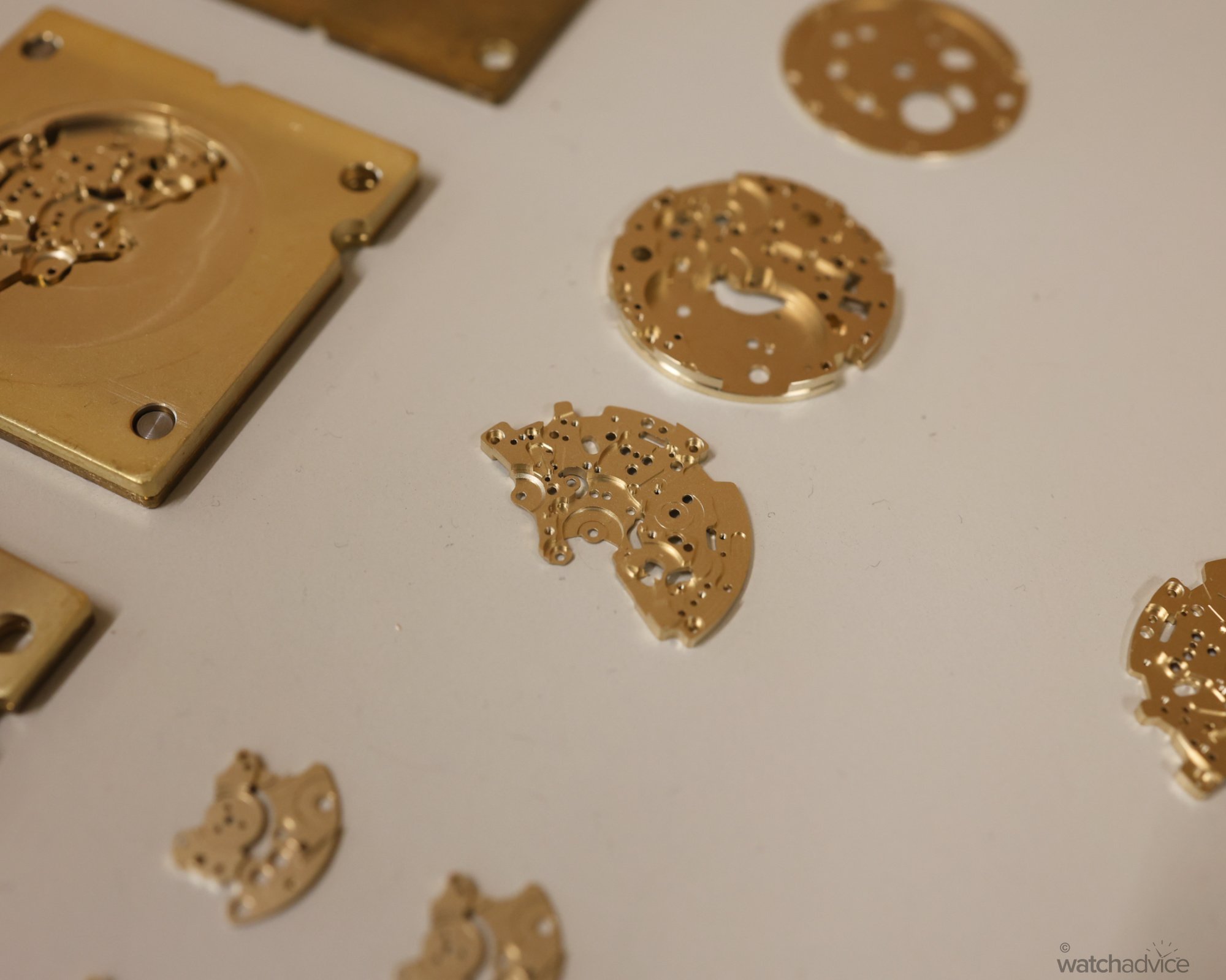

Depending on the components needed, the plates all end up forming the end shapes and specifications required for the movements in question. Breitling now has three manufacture movements being produced in-house – the B01 Chronograph, the B19 Perpetual Calendar Chronograph and the new B31 time only. All begin their life here.

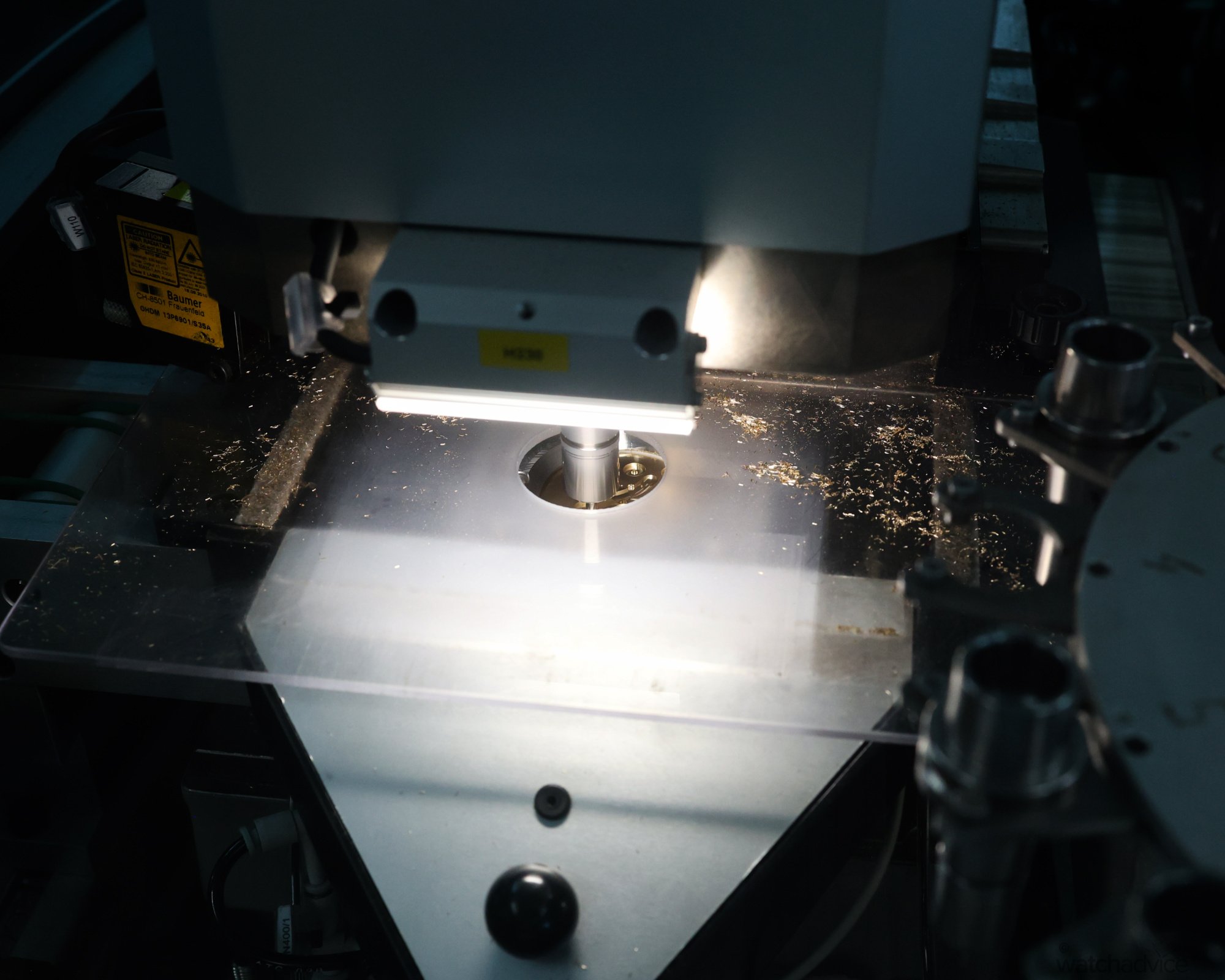

As mentioned, Breitling uses a combination of automation and humans to create the movements. Where time can be saved, and accuracy assured, the machines do their thing, and like most Manufactures, the majority of these base plates and bridges are all done this way. Seeing it in action was actually great as we followed the raw brass through the production line to see how Breitling has designed this process. I must say, highly efficient!

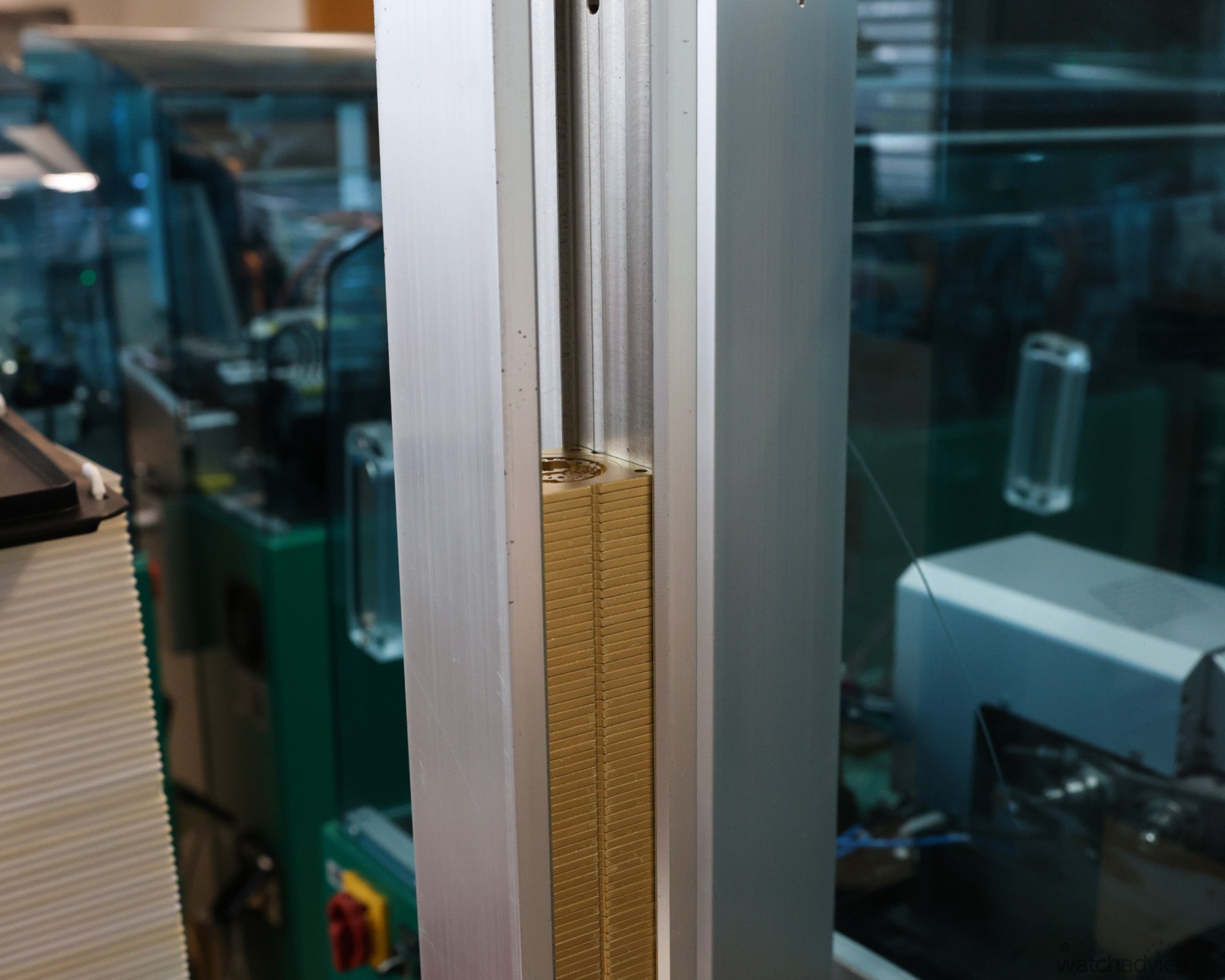

The pieces of brass enter the milling machines you see in the first image below, and are bored and cut to specification, which can be seen in the second image. Then the plates are put into a conveyor, seen in the last image, where they move along to be cleaned following the milling process.

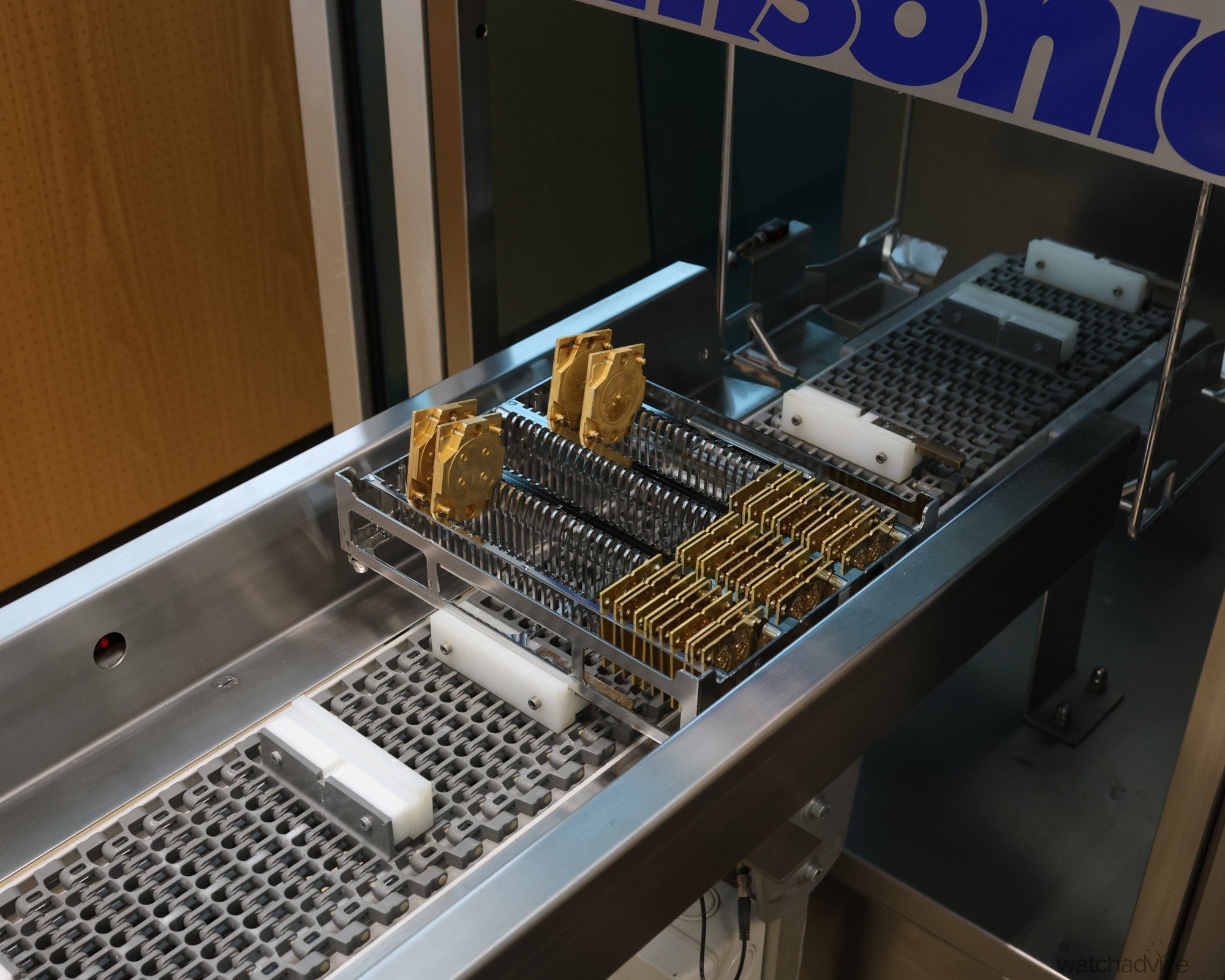

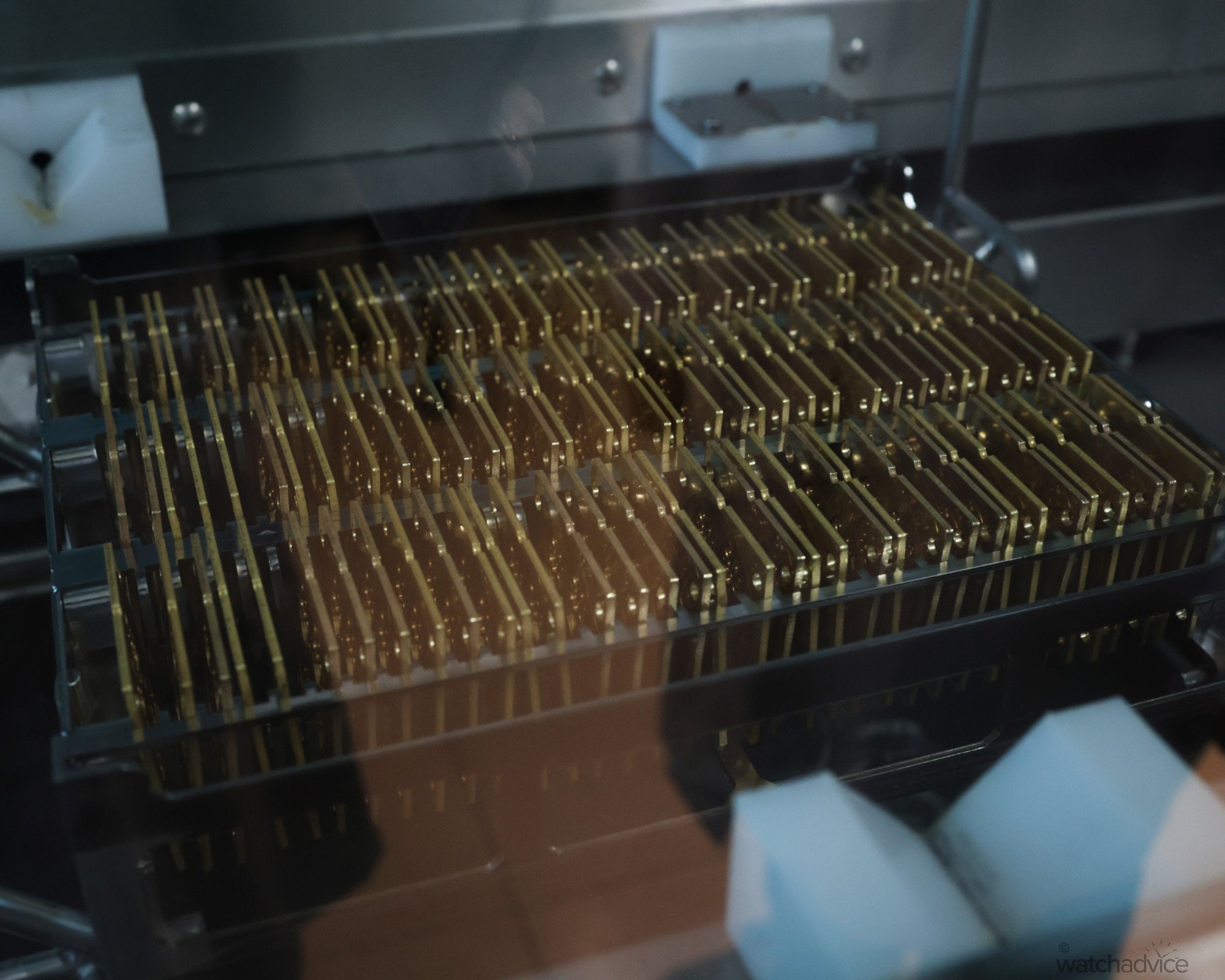

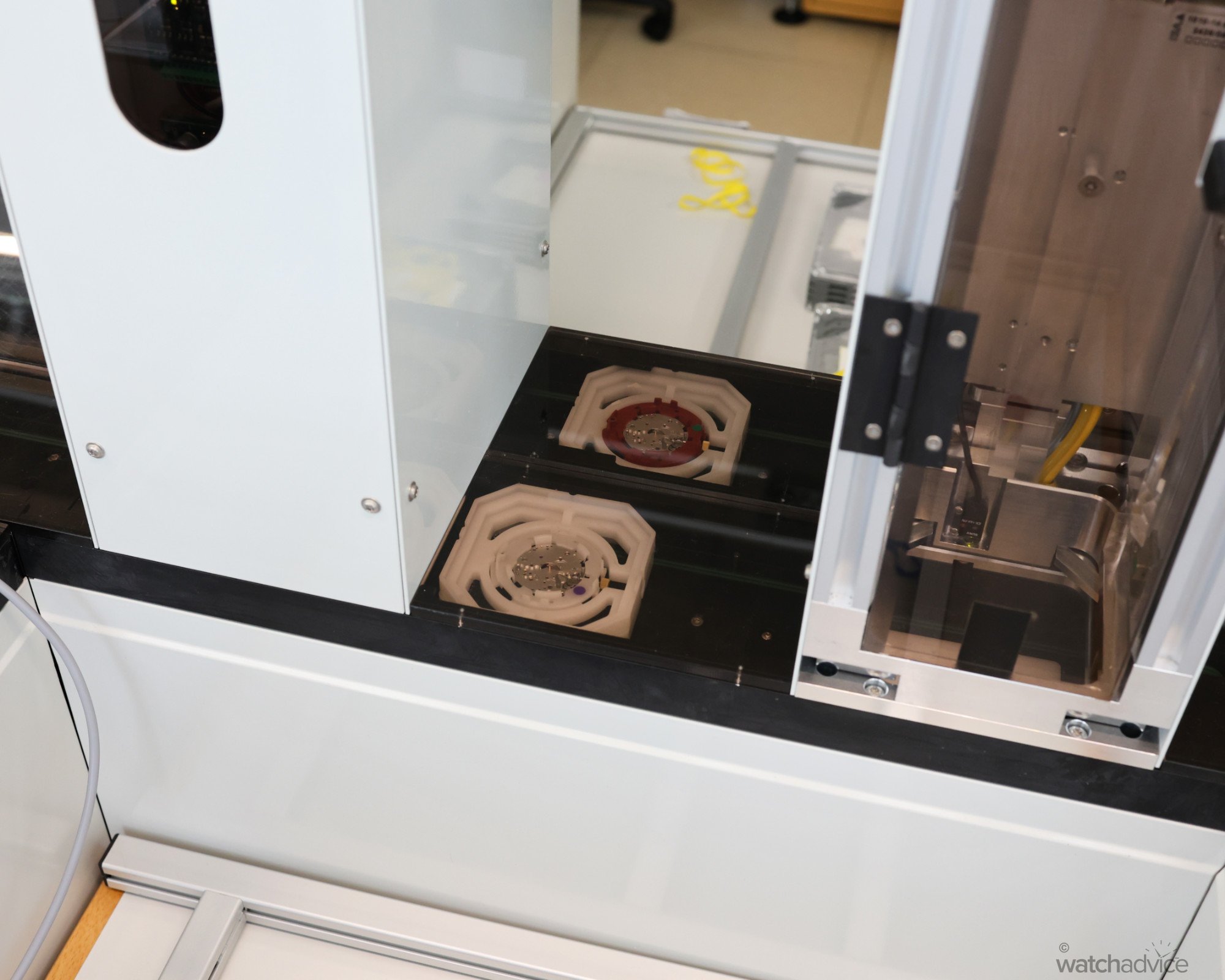

The components get dropped into a cleaning conveyor that then moves through an ultrasonic bath, ensuring all the small particles and metal dust is off the movement components before they are finally cut out and ready for finishing and then assembly. As you can see below, the conveyor is loaded with some of the components heading in, and in the second image, a batch of the components is being ultrasonically cleaned behind the glass.

Once the round base plates are cut out, the same applies to the bridges and other components. Breitling takes all the leftover materials, including metal shavings and dust, and recycles them to reduce both waste and environmental impact. Many brands are now doing this as part of the effort to reduce waste in the environment, and it is good to see that some are then reusing this in watches themselves, so it is kind of a 360-degree moment.

Humans And Robots Working Together

When the Breitling Chronometrie was set up, the vision was to rethink how a workshop could produce high-quality watches at scale. It is the old adage – think and work smarter, not harder. So, when the full Manufacture was opened in 2009 to facilitate the in-house B01, a new way of production was introduced, a fusion of automation, robots and humans all working seamlessly together to make a movement that is reliable, accurate, COSC certified and at scale with all the quality checks along the way. The idea behind this was simple. Let humans do what they do best, and let the machines do what they do best.

Seeing this in action, it makes a lot of sense. It is also pretty refreshing that Breitling is open about this as well. At the end of the day, Breitling wants to produce the best watches and movements possible, meaning that when you have one on your wrist, it performs as it should. From my personal experience, my Super Avenger and SuperOcean Heritage Chronograph ran flawlessly in the time I had them, and yes, the SuperOcean was one I slightly regret letting go!

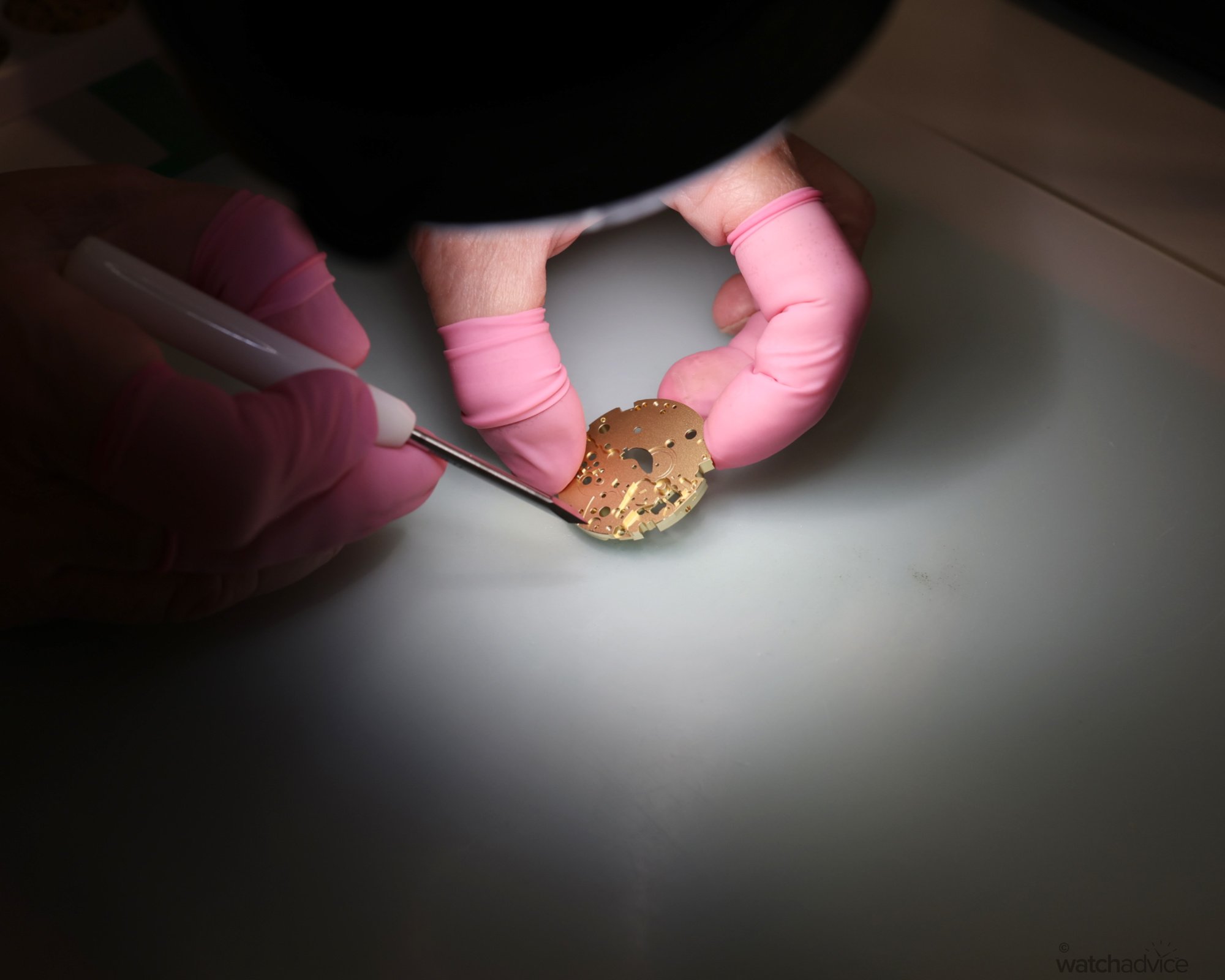

As we walked from the milling and machining processes, we entered the workshops where the finishing, assembly and quality checks take place. But, before this, the milled base plates and bridges are checked and hand-finished by expert watchmakers. This process needs the human touch, as the fine edging and finishing is too delicate for machines to do, especially to the level Breitling requires.

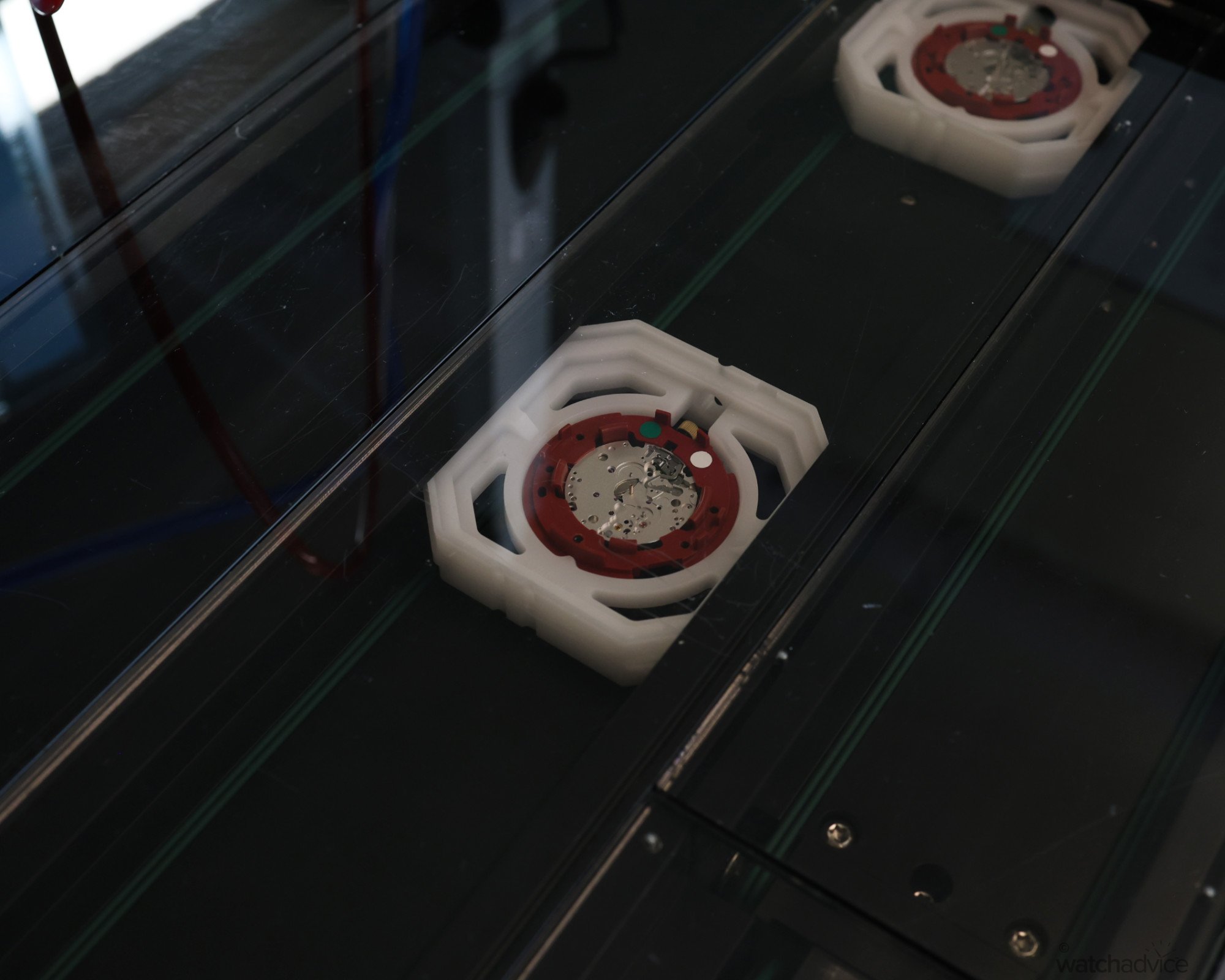

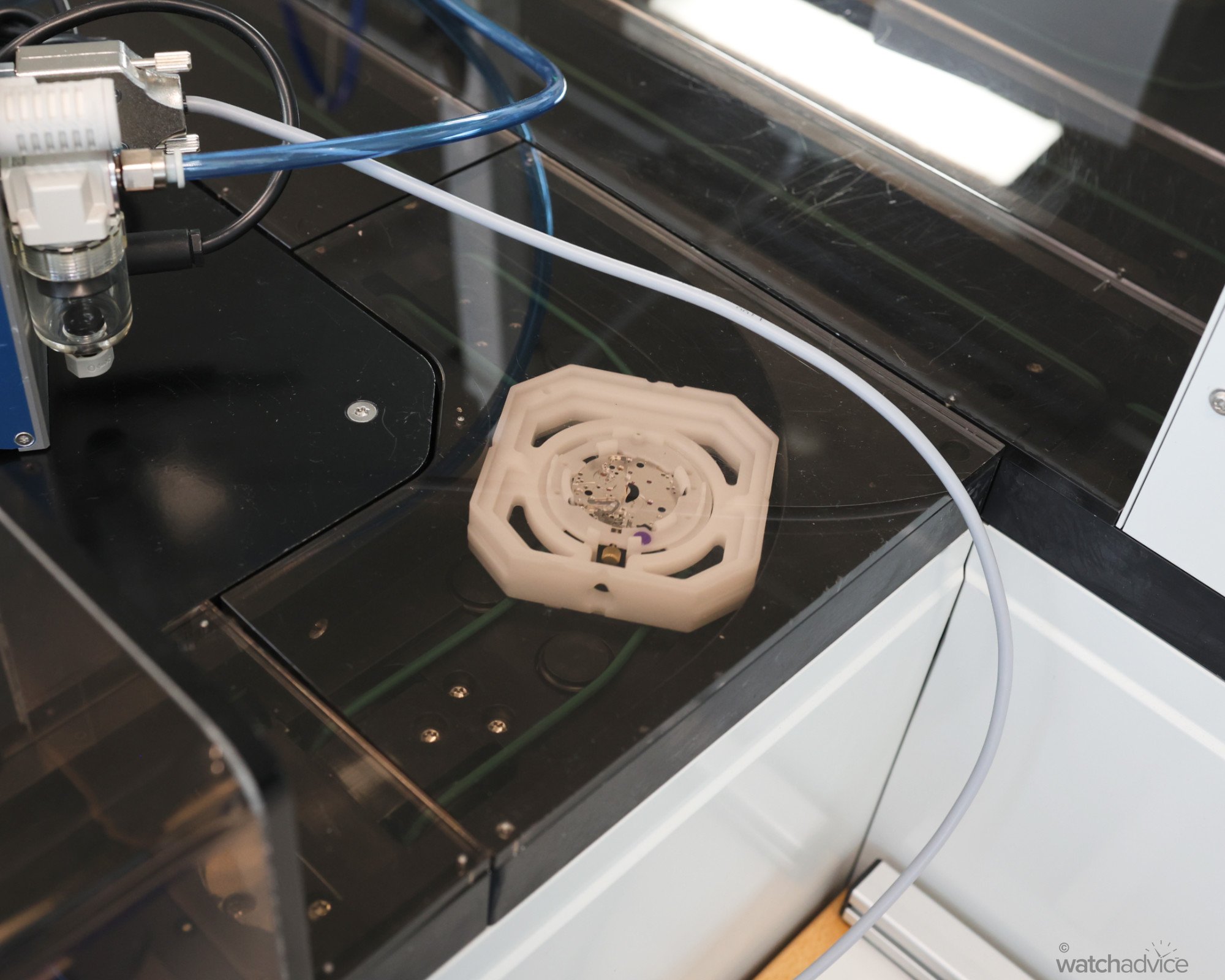

Once finished, the components are ready for assembly. Breitling has created a space where the watchmakers can work easily and freely, and for certain elements, the machines assist, making the day-to-day life of the watchmakers a little easier, but also speeding up the process across the assembly phase. One of these is the rubies used in the bridges. If you have ever seen a single ruby used in watchmaking up close, you’ll notice that they are very small for starters, but also, one side is flat, the other rounded. The flat side drops into the small hole in the bridge, and the pinion from the wheels and gears then pivots in the rounded side, creating less friction. Understandably, these are incredibly fiddly, so here, the robots help but making sure the jewels are all the right way. The lubricants are also administered by machines as the amount that is needed is very small (I could hardly see it with the naked eye) so this ensures the exact amount is added with zero spillover.

The different components of the movements are then shuffled along and placed in a sushi train-style set-up, ferrying the movements along to each workstation so the watchmakers can then do their bit. In fact, Breitling actually calls this the “Sushi Shop” as it is so similar to a Sushi Train! The benefit of this is two-fold, as I see it. One, it saves time having to manually pick up a tray of movements and take it to the next person working on the movement, which is how a lot of other Manufactures do it. The watchmaker places the movements into a tray, sticks these up, and once a certain number are completed, the watchmaker takes the tray over to the next workstation. Breitling has eliminated this, as the movements all travel along under the workbenches, visibly through a clear countertop and arrive at the next station ready to be worked on.

The second benefit, which as a byproduct creates efficiencies and saves time, is that each watchmaker on the line works on only a portion of the movement. This means that each becomes essentially an expert at putting those components in place, which can be done quickly, efficiently and most importantly, correctly without error. Fewer errors mean less time in quality checks, and less chance of a movement having anything wrong with it. This method isn’t unique to Breitling; other brands either assemble them fully with each watchmaker or have a similar set-up, with each focusing on smaller elements. What makes this more unique to Breitling is the Sushi Train-style set-up.

Accuracy And Reliability Ensured

Once the majority of the movement is complete, it is tested in the workshop in all positions for tolerances. As all Breitling movements, whether made by Breitling or not, are COSC certified, Breitling needs to make sure these hold up to the COSC’s stringent tests. So before they are cased up, the finished movements are sent to the test area, calibrated and then measured in different positions over time. Once the movement is calibrated to COSC standards, it can be sent off for the official certification.

Before a Breitling watch hits the shelf, the watch undergoes around a thousand tests, from start to finish, including tolerances in the machining process, boring process, lubrication, hairspring checks and then finally, for durability via tests that simulate 16 years’ worth of aging and of course, the COSC. Some of these are done by the robots, and some are done by humans, depending on the type of quality check needed. It is a good reassurance that each and every Breitling that passes through this facility is the best it can possibly be.

The Final Touches

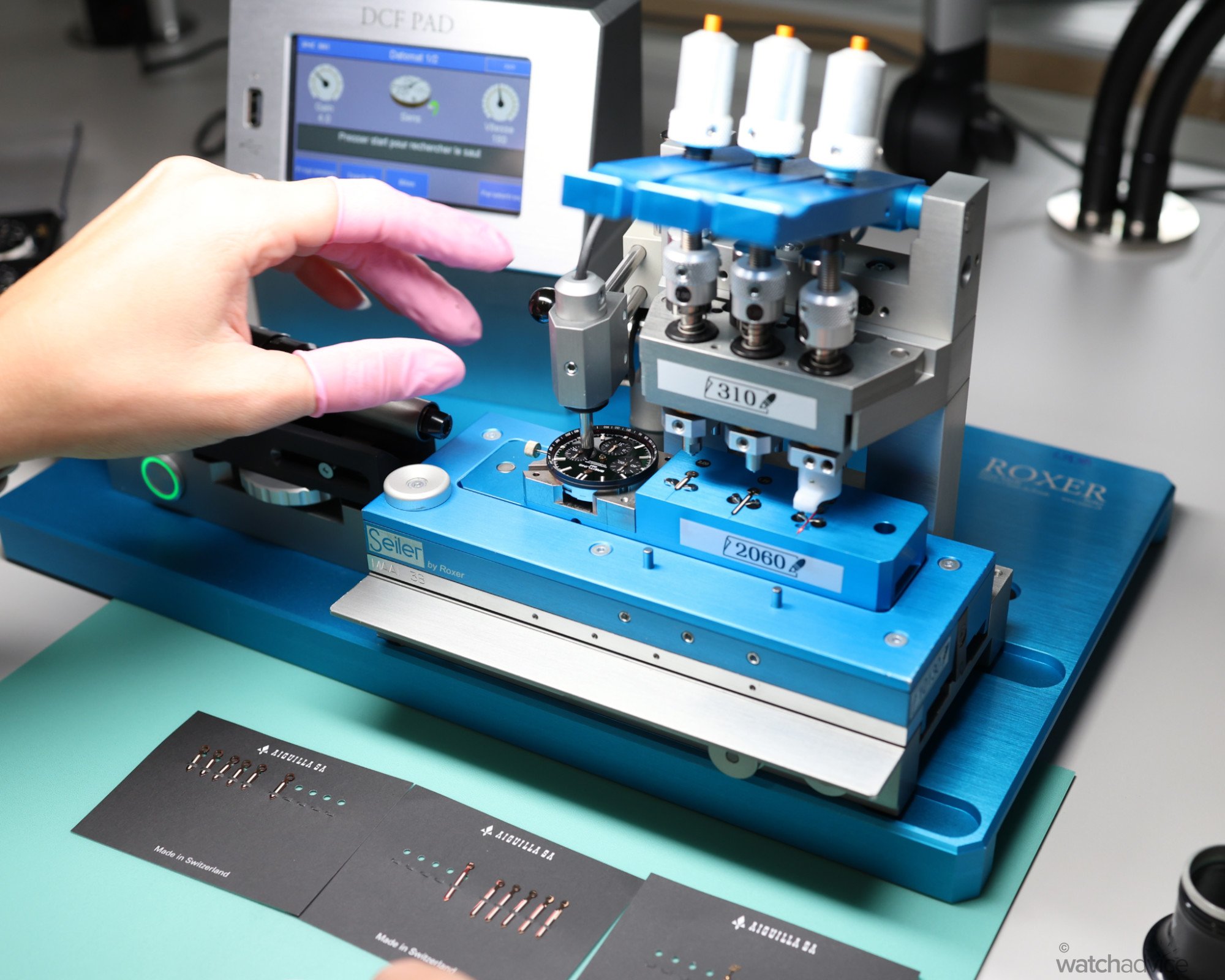

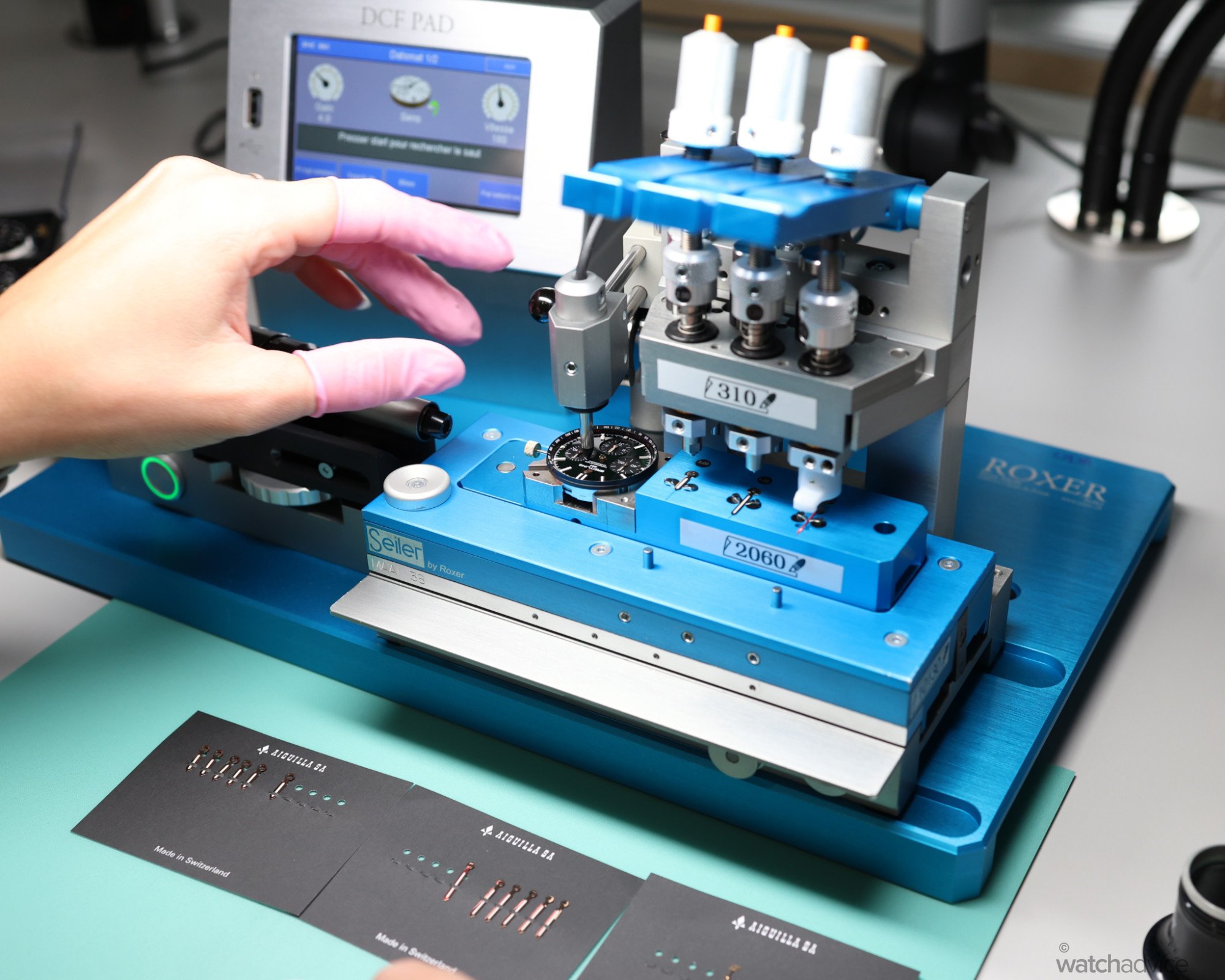

Once the movements are safely back in the hands of Breitling, the final touches are put on the dials, hands, and then cased up into the final product. Again, this is all done by the watchmakers at Breitling, who ensure that each watch is finished to the highest standard, and human hands take over where the machines are not able to do so. After years of experience, the watchmakers have such a great command over their hand movements, and they can manoeuvre the parts easily where as machines are not able, and even things like applying the right amount of pressure to the hands when placing them on the dial takes a soft but firm touch.

Before each watch is cased, the dials are applied to the front side of the movement, and once in place, the watchmakers then place each hand, including the sub-dials on one by one, ensuring they are in the correct positions for the time, the chronograph seconds and sub-dials. It is essential that this step is performed properly; otherwise, once the case is closed, the hands won’t align back to the 0 position.

Last, by not least, each movement with finished dials and hands is cased up. Each watchmaker takes care in placing the movement into the case, making sure it is free of any dust or particles on the movement, dial and crystal. The last thing you want is specs on the inside!

All Breitling movements that pass through the Chronometrie essentially undergo this process. The Manufacture movements – B01, B31 and B19 travel the full journey, whereas the non-Manufacture movements, those that are made by Breitling’s movement partners like ETA, Sellita or Dubois-Depraz, will come into the manufacture and then be finished, calibrated, and tested to Breitling standards. Either way, Breitling is ensuring that each calibre is of the same standard and adheres to COSC.

The Breitling Experience

No visit to Breitling would be complete without experiencing the Breitling hospitality. If you head into a Breitling Boutique, you will experience something similar. Each boutique is set up to be less of a store, and more like a clubhouse, for lack of a better word. Upstairs on one of the upper levels at the Chronometrie, you are able to get the same experience, with a fully equiped bar, lounge area to relax in, and the full range of Breitling collections on display.

However, not only is there a fully equiped bar to relax and enjoy, Breitling has set up a Heritage exhibit to complement this. Guests to the Manufacture can walk through Breitling’s 141 years of history, similar to the travelling exhibition that was in Sydney and Melbourne last year. With many current production pieces stemming from historical roots, it is well worthwhile taking time to see where all these iconic models come from. Navitimer, SuperOcean, Top Time, Chronomat and Premier – the list goes on!

As we ended our time at the Breitling Chronometrie, we had one last stop on the way. We could not do a Breitling visit without travelling down the road into the town of La Chaux-de-Fonds to Rue de Montbrilliant, where Leon Breitling set up the first Manufacture, after relocating his small workshop there in 1892.

Fun fact – the Breitling family lived here in the two end wings, as well as having the Manufacture in the centre. Even after Willy Breitling sold the business to Ernest Schneider, the brand would continue to make watches here until the new Chronometrie was built in 2001, and as explained, expanded in 2009. Today, the Manufacture on Montbrilliant has turned into apartments, but the Breitling logo is still displayed proudly on the entrance. The entryway into one section of the building still has the old artwork on the wall, as part of an effort to preserve the brand’s history.

With the quick trip to the original Breitling Chronometrie short, but sweet, it was time to head back to Geneva. For us, this was an educational visit, like most Manufacture visits are, but I felt that this one in particular was special. It’s rare that you get a personal guided tour with no other press or VIPs in the group, just the Watch Advice team of myself, Chamath and Sam, guided by Breitling’s Head of VIP Experience, Fabrice Riat – a wealth of knowledge when it comes to Breitling. The fact that they hoisted the Australian flag for us as part of the welcome and hospitality was something we had not experienced before, and a very nice touch.

But, on top of this, Breitling was one of my very first luxury watches I was able to purchase, my old 48mm Super Avenger, which served me well for almost 10 years. I’ve said before, Breitling is one of the few brands that I have loved since I really got into watches, and I know that for Chamath and Sam, they feel a similar way too, as Breitling was one of their first major pieces. So it was amazing that we got to experience the brand up close and personal, unfettered and see the journey of their Manufacture movements from start to finish.

A big thanks to the team and Breitling in Australia for organising, and for the team in Switzerland, especially Fabrice, for hosting us!